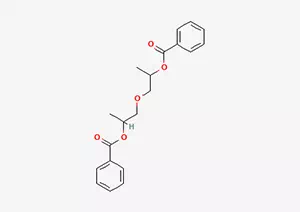

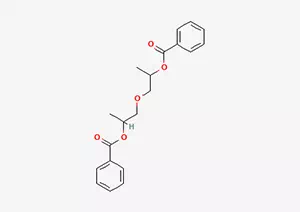

Benzoflex 9-88 CAS 27138-31-4 Dipropylene Glycol Dibenzoate Information

Chemical Name | Benzoflex 9-88 |

Other Name | Oxydipropyl dibenzoate; Di(propylene glycol) dibenzoate; Dipropylene glycol dibenzoate |

CAS | 27138-31-4 |

EINECS | 248-258-5 |

Type | Organic raw materials |

Molecular Formula | C20H22O5 |

Molecular Weight | 342.39 |

Benzoflex 9-88 CAS 27138-31-4 Dipropylene Glycol Dibenzoate Properties

Boiling point | 232 °C5 mm Hg(lit.) |

density | 1.12 g/mL at 25 °C(lit.) |

vapor pressure | 0Pa at 25℃ |

refractive index | n20/D 1.528(lit.) |

Fp | >230 °F |

storage temp. | Sealed in dry,Room Temperature |

Water Solubility | 8.69mg/L at 20℃ |

Stability | Stable. Combustible. Incompatible with strong oxidizing agents. |

What is Benzoflex 9-88 CAS 27138-31-4?

There is a highly regarded substance - benzozol 9-88, which is also known as dipropylene glycol dibenzoate (DPGDB). This substance has a unique chemical structure and is a highly soluble benzoate plasticizer. In its molecular structure, there is a special ether bond. This ether bond acts like a delicate bridge, closely connecting two benzoic acid groups together, and its main component is dipropylene glycol dibenzoate.

It is worth mentioning that benzoisole lex 9-88 holds an important position in the field of environmental protection. It is an ideal alternative to phthalate plasticizers that is highly recommended by the European Union. As a plasticizer in line with the concept of environmental protection, benzodiazepine lex 9-88 has been widely used in many fields due to its excellent performance and environmental protection characteristics.

In the field of water-based adhesives, it is ubiquitous. Whether it is the common white latex glue in daily life or the woodworking adhesive used for wood bonding in the woodworking industry; Whether it is panel adhesive, used for the firm splicing of various panels, or paper packaging adhesive, ensuring the stability of paper product packaging; Or for composite adhesives, cigarette adhesives, etc., benzophenol lex 9-88 plays a crucial role, providing good plasticizing effects for these adhesives and endowing them with better flexibility, adhesion and stability.

In addition to the field of water-based adhesives, benzophenol lex 9-88 also performs well in sealing materials. In polysulfide sealant and polyurethane sealant, it can effectively improve the performance of the sealant, enhance its sealing effect and durability. Meanwhile, in grout, it can also play a crucial role, enabling the grout to better fill the gaps and enhance its crack resistance and water resistance.

In the field of PVC products, the application of benzodiazepine lex 9-88 is even more extensive. From various toys loved by children to beautiful and practical elastic floors; From gloves to protect hands to various PVC plastic-coated products; Then, for Testerin, water hoses and artificial leather, etc., benzophenyl lex 9-88 can add flexibility and durability to these PVC products, making them more in line with market demands and usage requirements.

Not only that, in the production process of polyurethane elastomers/rubber rollers, benzophenol lex 9-88 is also an indispensable additive. It can optimize the performance of polyurethane elastomers and rubber rollers, enhance their elasticity and wear resistance, and extend their service life.

In the coatings and inks industry, benzophenol lex 9-88 also plays a significant role. It can endow coatings and inks with excellent leveling and adhesion, enhancing the quality and appearance of the coating.

In addition, in the field of pesticides, benzozol lex 9-88 can be used as an auxiliary component to improve the performance and stability of pesticides and enhance the application effect of pesticides. In terms of fluorescent materials, it can also contribute to the performance improvement of fluorescent materials, enabling them to achieve better fluorescence effects in various fields.

Benzoflex 9-88 CAS 27138-31-4 Uses

In the vast field of chemical materials today, dipropylene glycol dibenzoate, as a highly distinctive benzoate plasticizer, has demonstrated its unique and outstanding performance. This plasticizer has the characteristic of being highly soluble. It can dissolve rapidly and completely in various chemical solvents and reaction systems, providing great convenience for subsequent chemical reactions and material processing.

From an environmental protection perspective, dipropylene glycol dibenzoic acid has the significant advantage of being low-toxic and environmentally friendly. In the context of an era that increasingly emphasizes environmental protection and human health, this feature makes it stand out among numerous plasticizers. Compared with some traditional plasticizers, it causes minimal harm to the environment and living organisms, which is in line with modern society's pursuit of green and sustainable development.

In terms of physical properties, its curing temperature grade is low, which means that during the material processing, good curing effects can be achieved without excessively high temperatures. This not only reduces energy consumption, but also minimizes problems such as material decomposition and deterioration that may be caused by high temperatures, thereby enhancing production efficiency and product quality. Meanwhile, it has high plasticizing performance, which can effectively reduce the glass transition temperature of the material, enabling the material to have good flexibility and processability at a relatively low temperature, greatly expanding the application range and processing conditions of the material.

In terms of filling characteristics, dipropylene dibenzoate has demonstrated an excellent capacity to withstand the filling amount. During the material preparation process, it can accommodate a large amount of fillers without significantly affecting the basic properties of the material. This feature enables the cost to be reduced and the cost performance of the product to be improved while ensuring the material performance. In addition, it also has excellent cold resistance. Even in low-temperature environments, it can maintain the stable performance of the material without showing signs of embrittlement or cracking, ensuring the reliable use of the material under various climatic conditions. Its anti-pollution property is also very outstanding. It can effectively resist the erosion of external pollutants and maintain the appearance and performance of the material without damage.

For this reason, dipropylene glycol dibenzoate has been recognized and recommended by the European Union, and is regarded as an ideal alternative to traditional phthalate plasticizers. As an environmentally friendly plasticizer, it has been widely used in many fields.

In the field of synthetic materials, it is widely used in PVC synthetic plastics. During the processing of PVC, dipropylene glycol dibenzoic acid can be evenly dispersed between the polymer molecular chains, increasing the fluidity of the molecular chains and thereby enhancing the flexibility and processing performance of PVC. In water-based adhesives, it can improve the adhesion and stability of the adhesive, enabling it to form a strong bond on the surfaces of different materials. For polysulfide sealants and polyurethane sealants, the addition of dipropylene glycol dibenzoic acid can enhance the elasticity and durability of the sealant, ensuring it maintains a good sealing effect during long-term use. In the production of artificial natural leather, it can endow the leather with a better hand feel and texture, while enhancing its strength and wear resistance.

Benzoflex 9-88, as a specific product form of dipropylene glycol dibenzoate, also has excellent performance and wide applications. It can be used as a plasticizer for important materials such as polyvinyl chloride, polyvinyl acetate and polyurethane. In polyvinyl chloride (PVC), Benzoflex 9-88 not only has a plasticizing effect but also acts as a solid solvent, which can be fully compatible with PVC molecules and improve the processing performance and physical properties of PVC. Its low volatility feature ensures that during processing and use, the material's performance will not change due to the evaporation of plasticizers, guaranteeing the stability and durability of the material. The good resilience enables the material with Benzoflex 9-88 added to quickly return to its original state after being subjected to external forces, thereby increasing the service life of the material. What stands out particularly is its oil resistance and stain resistance, which makes it perform well in some application scenarios with high requirements for oil resistance, such as high-filling PVC flooring products and extruded plastics. In these applications, Benzoflex 9-88 can enhance the processability of the material, making it easier to form and process. At the same time, it can reduce the processing temperature and shorten the processing cycle, thereby improving production efficiency and reducing production costs.

When Benzoflex 9-88 is used in non-filled films, sheets and pipes, its excellent transparency and surface area gloss are even more remarkable. It can endow these materials with good visual effects and meet the demands of some application scenarios with high requirements for appearance quality.

In addition to its applications in the above-mentioned fields, benzoflex 9-88 has also demonstrated unique value in some special fields. For example, it can be used as a diluent for preparing polysulfone film layers by the thermal cracking method. In fields such as water treatment and food processing, where there are extremely high requirements for the safety and performance of materials, the application of benzo flex 9-88 provides strong support for the development of related technologies. Meanwhile, it can also be used as a plasticizer for polyvinyl chloride (PVC), for manufacturing diamond-coated PVC, providing a key additive for the production of this high-performance material.

Benzodiazepine 9-88 is a highly soluble polar plasticizer, and this characteristic makes it have good compatibility with various polar polymers and rubbers. In applications such as latex sealants, adhesives and sealants, coatings, and vinyl plastic sols, dipropylene glycol dibenzoate can fully exert its plasticizing effect and improve the performance of materials.

In the two-component polyurethane system, dipropylene dibenzoate has demonstrated excellent compatibility and effectiveness. It can be uniformly mixed with other components in the system to work together and improve the overall performance of the polyurethane system. In the production of cast polyurethane products, its characteristics of low curing interference and good compatibility are particularly prominent. It can be well combined with other materials without affecting the curing process of the product, ensuring the stability of the product quality.

In addition, dipropylene dibenzoate can also increase the filler load of the polyurethane system. Through a good synergistic effect with the filler, it can enhance the tear strength and resilience of the material. Meanwhile, it can reduce the expansion and deformation of materials in specific solvents, enhance the stability of materials in different solvent environments, and further expand the application scope of polyurethane materials.

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.