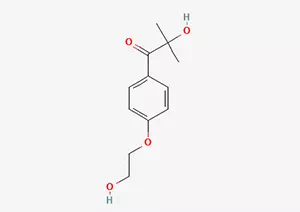

What is 2-Hydroxy-4-(2-Hydroxyethoxy)-2-Methylpropiophenone CAS 106797-53-9?

Among numerous photoinitiators, 2-hydroxy-4 '- (2-hydroxyethyl) -2-methylhydrobenzone, which is commonly known as photoinitiator 2959, shows more obvious advantages when compared with Irgacure 1173. One of the most prominent features is that it has relatively low volatility and odor. It should be known that in the actual application process, the lower volatility means that during the usage process, the photoinitiator 2959 can exist more stably in the system and will not easily volatilize and dissipate, thereby ensuring the continuity and effectiveness of its photoinitiation effect. The characteristic of a lower odor not only enables operators to be in a relatively more comfortable and healthy environment when coming into contact with and using this photoinitiator, reducing the physical discomfort and adverse effects on the operating environment that may be caused by pungent odors, but also in some application scenarios with strict odor requirements, For instance, in terms of material processing related to food packaging, interior decoration, etc., photoinitiator 2959 can also better meet the usage requirements.

More importantly, there are high-energy hydroxyl groups in the photoinitiator 2959 molecule. This special structure endows it with unique chemical properties, enabling it to be easily grafted onto polymer molecules. Specifically, during the chemical reaction process, this high-energy hydroxyl group can interact with polymer molecules and be ingeniously "grafted" onto them through chemical bonds. This grafting effect brings many conveniences, the most notable of which is that it makes it easier to operate in the subsequent processing. For instance, when preparing some composite materials or modifying the surface of materials, photoinitiator 2959 can better integrate with the polymer matrix by taking advantage of this property, be uniformly dispersed in it, and then efficiently initiate polymerization reactions under light conditions to achieve processing purposes such as material curing.

Photoinitiator (abbreviated as PI) plays an indispensable and crucial role in the entire UV healing product system. It is like an "engine", playing a vital and decisive role in the speed of UV curing. The so-called photoinitiator is a kind of chemical substance with special functions. It can effectively absorb external radiant energy, just like a sensitive energy receiver. When exposed to light of the appropriate wavelength, it can rapidly absorb radiant energy and thereby stimulate a series of photochemical changes. Meanwhile, it also has the ability to generate high-energy intermediates with the ability to initiate polymerization (which can be free radicals or cations). These high-energy intermediates act like "catalysts", promoting the polymerization reaction of monomers or prepolymers, thereby achieving the curing and shaping of the material.

According to the different levels of radiation power absorbed, photoinitiators can be classified in detail, mainly into two categories: ultraviolet initiators and visible light initiators. Ultraviolet initiators mainly absorb the energy in the 250 to 420nm region of the ultraviolet band. Within this specific wavelength range, their molecular structure can be activated, thereby triggering subsequent photochemical reactions. Visible light initiators, on the other hand, focus on absorbing the energy in the 400 to 700nm region of the visible light band to achieve the corresponding initiation polymerization function. This classification method helps us precisely select the appropriate type of photoinitiator based on different lighting conditions and application scenarios, thereby achieving the best usage effect.

From the perspective of different active intermediates, photoinitiators can be further classified into completely free extreme photoinitiators and cationic photoinitiators. Due to the differences in the systems that generate free radicals, free radical photoinitiators can be further classified into two types, namely pyrolytic photoinitiators and hydrogen capture photoinitiators. Under the current technological application background, ultraviolet curing technology has become the main adopted curing technology due to its many advantages, such as fast curing speed, low energy consumption and environmental friendliness. Correspondingly, the photoinitiators used in practice are mostly ultraviolet initiators to meet the performance requirements of photoinitiators in the ultraviolet curing process.

Photoinitiator 2959 has a wide range of applications and can be used in UV healing formulations for the surfaces of wood, metal, plastic and paper. When treating the surface of wood, photoinitiator 2959 can help UV coatings adhere better to the wood. Through light-induced polymerization reactions, it forms a strong and wear-resistant coating, enhancing the surface performance and aesthetic appeal of the wood. For metal surfaces, it can ensure that the UV healing formula is uniformly cured on the metal substrate, enhance the adhesion between the coating and the metal, and play a good role in anti-corrosion, decoration, etc. In the application on the surfaces of plastics and paper, it can also achieve efficient curing effects, endowing the materials with better physical properties and appearance.

It is worth mentioning that the hydroxyl useful groups in the photoinitiator 2959 molecule play a significant role, greatly enhancing its solubility in water-based coating formulations. This enables photoinitiator 2959 to be more evenly dispersed in the water-based coating system, avoiding problems such as agglomeration and sedimentation, ensuring the stability of water-based coatings during storage and use. At the same time, it also allows it to more effectively initiate polymerization reactions under light, achieving good curing of water-based coatings.

Once again, it is emphasized that photoinitiator 2959 has lower volatility and odor than Irgacure 1173, and this advantage is particularly prominent in practical application scenarios. Moreover, its active hydroxyl groups can be conveniently implanted onto polymer particles, and this feature makes the entire material system more convenient and flexible during the processing. For instance, when manufacturing plastic products with complex shapes or conducting multi-layer composite processing on materials, this property of photoinitiator 2959 enables it to better combine with polymer particles. As the processing progresses, it can function evenly, ensuring product quality and processing efficiency.

In addition, due to its unique living properties, photoinitiator 2959 is particularly recommended for UV formulations that require the evaporation of moisture through heating and air movement before curing. In some UV curing systems that are sensitive to moisture, it is often necessary to remove moisture from the material before curing. The unique properties of photoinitiator 2959 enable it to maintain good stability and functionality under such special process conditions, ensuring the smooth progress of the entire UV curing process and ultimately obtaining high-quality cured products.

2-Hydroxy-4-(2-Hydroxyethoxy)-2-Methylpropiophenone CAS 106797-53-9 Use

Among the numerous photoinitiators available today, photoinitiator 2959 holds an important position in related fields due to its unique properties and advantages. It is worth mentioning that photoinitiator 2959 has been strictly reviewed and approved for use by the FDA certification system. This certification fully demonstrates its outstanding performance in terms of safety and reliability.

In practical application scenarios, photoinitiator 2959 has demonstrated a series of remarkable characteristics. Among them, the feature of reducing odor is particularly prominent. In many processes involving the use of photoinitiators, unpleasant odors are often produced, which not only have adverse effects on the operating environment but also pose a potential threat to the quality of the final product. However, photoinitiator 2959 can effectively avoid this problem, ensuring that the surrounding environment remains relatively fresh during use and providing operators with a more comfortable and healthy working environment.

In addition to reducing odor, photoinitiator 2959 also has the advantage of reducing volatility. The release of volatile substances not only leads to the waste of materials, but may also cause environmental pollution, and at the same time affect the stability and durability of products. Photoinitiator 2959, through its unique chemical structure and properties, effectively reduces the generation of volatile substances, enabling better maintenance of the material's performance and quality during use and extending the product's service life.

In addition, reducing yellowing is also a significant feature of photoinitiator 2959. During long-term use or storage, many materials are prone to yellowing, which not only affects the aesthetic appearance of the product but may also indicate instability in the internal structure of the material or a decline in performance. Photoinitiator 2959 can largely suppress the occurrence of this yellowing phenomenon, ensuring that the material maintains its original color and performance for a long time, and improving the quality and market competitiveness of the product.

It is precisely because of these excellent properties that photoinitiator 2959 has been widely applied in the field of adhesives that do not come into direct contact with food. In these application scenarios, the safety and stability of materials are required to be extremely high. The low odor, low volatility and anti-yellowing performance of photoinitiator 2959 enable it to meet relevant standards and requirements, providing a reliable guarantee for the performance and quality of adhesives.

Further exploration of the chemical structure of photoinitiator 2959 reveals that it contains high-energy hydroxyl groups that cannot be cured by hydroxyethoxy groups. This special hydroxyl structure endows it with unique chemical activity, enabling it to actively participate in various chemical reactions. When interacting with other materials, this active hydroxyl group can effectively react with unsaturated materials, thereby triggering a series of polymerization reactions and achieving performance optimization and functional improvement of the materials.

In terms of specific applications, photoinitiator 2959 has wide applicability. It can be applied in water-based UV-curing systems with high melting points. In this system, due to the relatively low boiling point of water, higher requirements are placed on the thermal stability and compatibility of photoinitiators. Photoinitiator 2959, with its outstanding performance, can maintain stable chemical properties in high-temperature environments, effectively initiate photocuring reactions, and ensure the smooth operation of water-based photocuring systems.

Meanwhile, photoinitiator 2959 can also be applied to UV-treated powder layers. During the UV treatment process, the uniformity of the powder layer and the curing effect directly affect the quality of the final product. Photoinitiator 2959 can be evenly distributed in the powder layer. Under the irradiation of ultraviolet light, it can rapidly trigger a reaction, enabling the powder layer to cure quickly and evenly, and form a coating or material with good performance.

During the initiation process, photoinitiator 2959 is mainly used as a sensitizer for UV finishing agents, inks and adhesives. It can keenly sense the energy of ultraviolet rays and convert it into the driving force to trigger chemical reactions, thereby accelerating the curing process of UV coatings, inks and adhesives. Compared with traditional photoinitiators, the performance of photoinitiator 2959 is more outstanding. For instance, compared with (photoinitiator ITX + photoinitiator EDAB) and photoinitiator BDK, it demonstrates obvious advantages in multiple aspects.

Photoinitiator 2959 also has a unique property, namely, it is not consciously oxygen-restricted and has low volatility. In many photoinitiated reactions, the presence of oxygen often hinders the reaction, resulting in an unsatisfactory curing effect. However, photoinitiator 2959 can still maintain a good initiation effect in the presence of oxygen and is not overly disturbed by oxygen. Meanwhile, its low volatility also enables the reduction of volatile substance release during use, further enhancing the safety and environmental friendliness of the product.

In terms of surface curing, the performance of photoinitiator 2959 is also excellent. It can rapidly trigger a reaction on the surface of the material, forming a uniform and dense cured layer, effectively protecting the internal structure of the material and improving its surface performance. However, it should be noted that the spectral absorption band of photoinitiator 2959 is mostly in the short-wavelength band, which to some extent limits its application in certain specific scenarios. For example, in the UV pigment system, due to the absorption and scattering of light by the pigment, it may have a certain impact on the effect of photoinitiator 2959 in deep treatment. But even so, it can still play an important role in some specific formulations, such as in the relevant system applicable to photoinitiator 369.

Photoinitiator 2959 is a highly efficient and non-yellowing UV photoinitiator, which has significant advantages in initiating UV polymerization in unsaturated pre-polymerization systems. Especially in the application of acrylate materials, it can rapidly and effectively trigger polymerization reactions, enabling acrylate materials to cure and form rapidly, thus creating products with excellent performance. Meanwhile, for unsaturated polyester materials, especially those that need to reduce odor and water-based performance, photoinitiator 2959 can also play an important role. It can react with the unsaturated bonds in unsaturated polyester materials, improve the performance of the materials, reduce the generation of odors, and enhance the water-based properties of the materials.

An in-depth analysis of the molecular structure of photoinitiator 2959 reveals that the active hydroxyl groups in its molecule make it prone to react with unsaturated materials. This active hydroxyl group can interact with the double bonds or other active groups in unsaturated materials, thereby triggering a series of chain reactions and achieving the polymerization and curing of the materials. This excellent reactivity enables photoinitiator 2959 to play an efficient role in the photocuring process of various unsaturated materials.

In addition, photoinitiator 2959 is also applicable to standard ultraviolet systems. Under standard ultraviolet light conditions, it can fully absorb the energy of ultraviolet rays and convert it into the chemical energy that triggers the reaction, thus ensuring the smooth progress of the light curing reaction. Moreover, due to the hydroxyl practical group in its particles enhancing the solubility of photoinitiator 2959 in water-based covering formulations, it can also have a good application effect in water-based UV formulations. In water-based UV formulations, photoinitiator 2959 can be evenly dispersed in water and fully mixed with water-based resins and other components. Under the irradiation of ultraviolet light, it rapidly initiates a polymerization reaction to form water-based UV curing materials with excellent performance.

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.