2-Hydroxyethyl Acrylate CAS 818-61-1 HEA Information

Chemical Name | 2-Hydroxyethyl Acrylate |

Other Name | Hydroxyethyl acrylate; 2-(Acryloyloxy)ethanol; HEA |

CAS | 818-61-1 |

EINECS | 212-454-9 |

Type | Organic raw materials |

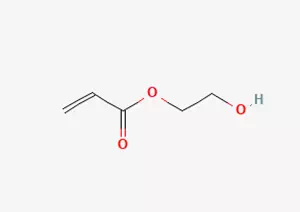

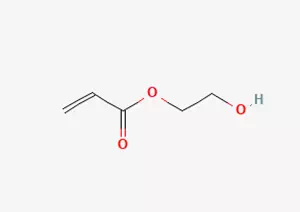

Molecular Formula | C5H8O3 |

Molecular Weight | 116.12 |

2-Hydroxyethyl Acrylate CAS 818-61-1 HEA Properties

Melting point | -60 °C |

Boiling point | 90-92 °C12 mm Hg(lit.) |

density | 1.106 g/mL at 20 °C |

vapor density | >1 (vs air) |

vapor pressure | <0.1 mm Hg ( 20 °C) |

refractive index | n20/D 1.45(lit.) |

Fp | 209 °F |

storage temp. | 2-8°C |

pka | 13.85±0.10(Predicted) |

form | Oily Liquid |

color | Yellow to brown |

Water Solubility | soluble |

Sensitive | Light Sensitive |

What is 2-Hydroxyethyl Acrylate CAS 818-61-1 HEA?

Plastic, as a material widely used in modern life, is usually composed of high-molecular polymers and various components used to change the structure of products. These components work together to endow plastics with diverse properties and characteristics.

Among them, the formation of polymers is a complex and orderly process. It is produced by the gradual reaction between monomers. During this process, the monomer molecules combine with each other and gradually form larger particles. During this polymerization process, dimers, trimers and molecules with larger molecular weights (MW) emerge one after another, and these molecules are chemically called oligomers. They are like the cornerstones of a building, constantly accumulating and combining until they eventually form a complete polymer.

Among numerous monomers, 2-hydroxyethyl acrylate is an extremely important one. During the development of plastics, there is a situation closely related to monomers. That is, when only one monomer is used to develop polymers, such polymers are called homopolymers. For example, polyethylene, which we are familiar with, is a homopolymer formed through the polymerization reaction of ethylene monomers and has its own unique physical and chemical properties.

However, if two or more different monomers are used for the polymerization reaction, the resulting polymer is called a copolymer. For example, the acrylone-ethylene copolymer is the result of the polymerization reaction involving two different monomers, propylene and ethylene. This copolymer combines the characteristics of the two monomers, thereby demonstrating performance different from homopolymers.

This crucial polymerization process is usually achieved by adding a small amount of catalyst or initiator. Take the manufacture of plastics containing 2-hydroxyethyl acrylate as an example. In this process, merely having monomers and catalysts is not sufficient. In order to customize the final product that meets various demands, many supplementary substances also need to be added.

These supplementary substances are classified into different additive groups or categories. For instance, plasticizers can enhance the flexibility and plasticity of plastics, making plastic products softer and easier to process during use. Fillers can improve the mechanical properties of plastics, reduce costs, and at the same time endow plastics with some special functions, such as enhancing hardness and wear resistance. Antioxidants can prevent plastics from degrading due to oxidation during storage and use, thereby extending the service life of plastics. Ultraviolet stabilizers can protect plastics from ultraviolet damage, enabling them to maintain good performance even when used outdoors. Anti-ozone representative agents can enhance the resistance of plastics to ozone and play an important role in some special environments. Antistatic representative agents can reduce the accumulation of static electricity on the surface of plastics, avoiding safety hazards caused by static electricity and its impact on electronic devices. Organic stabilizers help maintain the chemical stability of plastics during processing and use. Thermal insulation stabilizers can maintain the temperature stability of plastics to a certain extent. Foaming representative agents can form bubble structures inside plastics, reduce the density of plastics, and at the same time improve their heat insulation, sound insulation and other properties. Flame retardants can prevent plastics from burning or delay the spread of fire, thereby enhancing the fire safety of plastics. In addition, to meet people's requirements for the appearance and odor of plastics, substances such as dyes and fragrances are also added.

2-hydroxyethyl acrylate (HEA) holds a unique position in the field of plastics, as it can form homopolymers and copolymers. Hea mainly plays an important role. On the one hand, it is often used as a copolymer monomer in polymer manufacturing, participating in polymerization reactions together with other monomers and contributing to the formation of copolymers with specific properties. On the other hand, it is also a chemical reactant in the production of chemical intermediates and participates in various complex chemical synthesis processes.

When manufacturing polymers, hea has a wide range of copolymer objects. It can be copolymerized with a variety of substances such as acrylic acid, acrylate, methacrylate, vinyl acetate, plastic chlorides, vinylidene chloride, styrene, butadiene, etc. This extensive copolymerization property endows hea with extremely high flexibility and adaptability in plastic preparation. It can be combined with other monomers to form copolymers with various properties according to different demands and application scenarios.

Not only that, carbon monoxide catalysts containing hea also come in a variety of types, including aromatic and aliphatic isocyanates, anhydrides and epoxides, etc. These catalysts play a crucial catalytic role in HEA-related chemical reactions, promoting the smooth progress of the reactions, enhancing reaction efficiency and the quality of the products.

Polymers and chemical intermediates made from hea have extensive applications in real life. In terms of automotive topcoats, they can provide automobiles with coatings that are aesthetically pleasing, durable and have good protective performance. In the field of architectural finishes, decorative materials with unique texture and performance can be created. It also plays an indispensable role in the manufacturing of UV-cured resins and adhesives. It is worth mentioning that approximately 50% of the world's hydrogen is used in the production of acrylic coatings for the automotive industry, which fully demonstrates the significance and wide application of HEA-related materials in the automotive sector.

2-Hydroxyethyl Acrylate CAS 818-61-1 HEA Uses

2-hydroxyethyl acrylate is a chemical substance with wide applications. It can undergo copolymerization reactions with various monomers and exhibit outstanding chemical properties. This substance not only performs well in terms of solvent resistance, crease resistance, water resistance, etc., but also plays an important role in the manufacture of thermosetting finishing materials, artificial rubber, and as a component of lubricating substances.

Specifically, after copolymerizing 2-hydroxyethyl acrylate with plastic monomers, the durability of the adhesive can be significantly enhanced, which is of great significance for improving the overall quality and service life of the product. During the papermaking process, it is used as a raw material for acrylic emulsion used in coatings, effectively enhancing the water resistance and strength of the paper, and meeting the modern industry's demand for high-quality paper.

In addition, 2-hydroxyethyl acrylate can be used as a reaction diluent and crosslinking agent in radiation treatment systems, providing new technical solutions for fields such as resin crosslinking agents, plastic and rubber modifiers. Its unique chemical properties have enabled it to be widely applied in numerous fields such as the manufacturing of thermosetting acrylic coatings, UV-curable acrylic coatings, photosensitive finishing agents, adhesives, textile treatment agents, paper processing, water quality stabilizers, and polymer products.

It is worth mentioning that the technology of preparing porous hydrogels by copolymerizing 2-hydroxyethyl acrylate of acrylic acid with crosslinking agents, as well as the method of synthesizing amphoteric block copolymers through reactive extreme polymerization using 2-hydroxyethyl acrylate as raw materials, have further expanded the application scope of 2-hydroxyethyl acrylate. The technology of preparing tunable hydroxyethyl polyacrylate by atomic transfer radical polymerization provides more possibilities for research and application in related fields.

In conclusion, 2-hydroxyethyl acrylate, as a multifunctional chemical substance, has a wide range of applications and excellent chemical properties, making it one of the indispensable important raw materials in modern industry.

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.