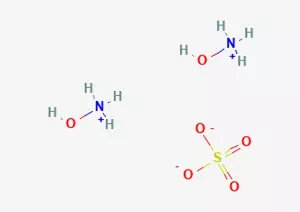

What is Hydroxylamine Sulfate CAS 10039-54-0?

Hydroxylamine sulfate (CAS 10039-54-0) is a highly active reducing agent and synthetic intermediate, widely used in the pharmaceutical, pesticide and materials industries. However, its strong corrosiveness, toxicity and environmental risks need to be strictly controlled. Core operating principles: Airtight protection, heat and moisture avoidance, and no contact with oxidants.

Hydroxylamine Sulfate CAS 10039-54-0 Use

Industrial and Synthetic Chemistry

Reducing agent: It is used for the reduction of metal compounds such as gold, silver and mercury

Organic synthesis: Synthesis of oxime, hydroxamic acid (Intermediate for pesticides/pharmaceuticals)

Rubber industry: As a vulcanizing agent to improve rubber performance

Professional field

Pharmaceuticals: Production of antibiotics (such as vitamin B₁₂) and anti-tumor drugs

Agriculture: Manufacturing insecticides (Methomil) and herbicides

Water treatment: High-efficiency dechlorinating agent

Analytical reagents: Selenium determination, developer (photographic development)

Hydroxylamine Sulfate CAS 10039-54-0 safety

Health hazard

Acute toxicity: Oral LD₅₀ in rats was 842 mg/kg, which was moderately toxic (harmful to swallowing).

Irritation: Corrosive to skin and eyes, contact may cause allergic reactions (R43)

Special toxicity: Long-term exposure may cause methemoglobinemia and neurological damage

Environmental risk

Aquatic toxicity: Highly toxic to aquatic organisms (R50), environmental release should be avoided

Protective measures

Operating requirements: Enclosed environment + local exhaust ventilation. Wear dust masks, acid and alkali resistant gloves and goggles

Leakage handling: Cover with plastic sheeting and collect. Do not rinse with water

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.