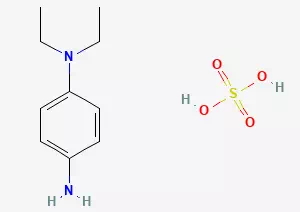

In the field of chemical engineering, there exists a substance with unique properties - a white or light red crystal-like substance. This substance can dissolve smoothly in water when in contact with it, demonstrating excellent water solubility. However, in alcohol, an organic solvent, its solubility is relatively weak, presenting only a slightly soluble state.

It is worth mentioning that this substance has the property of being highly oxidized. Once exposed to a suitable environment, it will rapidly undergo an oxidation reaction with oxygen in the air, and its color will also change significantly, rapidly transforming from the original white or light red to pink. This unique phenomenon provides a certain identification basis for its practical application and detection.

From the perspective of physical properties, its melting point falls within a relatively specific range, namely 184-186℃. This means that when the ambient temperature reaches this range, the substance will gradually change from a solid state to a liquid state. Once the temperature exceeds this range, it will return to a solid state or remain in a liquid state. This characteristic is of great significance for its control and application in related technological processes.

In terms of chemical synthesis, N, N, n-diethylaniline has a series of complex and crucial reaction processes. In the specific acidic environment provided by the hydrochloric acid tool, N, N, n-diethylaniline will undergo nitrosation reaction with sodium nitrite, thereby generating p-nitroso-N, n-diethylaniline hydrochloride. This reaction step requires strict control of reaction conditions, including the concentration of hydrochloric acid, temperature and reaction time, etc., to ensure that the reaction can proceed smoothly and achieve the expected product generation rate.

Then, the generated p-nitrosy-N, n-diethylaniline hydrochloride will react with iron powder. During this process, the iron powder acts as a reducing agent, minimizing the nitrosyl group and thereby generating p-amino-N, N-diethylaniline hydrochloride. This step of the reaction also requires precise operation and condition control, as factors such as the amount of iron powder used and the pH of the reaction system all have significant impacts on the reaction outcome.

Subsequently, by treating the generated p-amino-N, N-diethylaniline hydrochloride with alkali, its influence can be further reduced, making the entire reaction system more stable and controllable.

Finally, in order to obtain the target product, the method of sulfuric acid pickling can also be adopted. During this process, sulfuric acid undergoes a specific chemical reaction with the substances obtained from the previous reaction. After a series of chemical changes and physical treatments, the desired items are finally obtained.

Throughout the entire production process, the feed quota for basic raw materials has been precisely calculated and verified through practice. Among them, the feed quota for N, N-diethylaniline (with a purity of 95%) is 940kg/t, which means that for every ton of the target product produced, 940 kilograms of N, N-diethylaniline with a purity of 95% are consumed. The feed quota for sulfuric acid (with a purity of 98%) is 4000kg/t, indicating that the production of each ton of product requires 4000 kilograms of sulfuric acid with a purity of 98% to participate in the reaction. The feed quota for nitric acid (with a purity of 95%) is 577kg/t, that is, for every ton of this item produced, 577 kilograms of nitric acid with a purity of 95% is required as raw material. These precise feed quotas play a crucial role in ensuring product quality, enhancing production efficiency and controlling production costs.