Oleic Acid Infpormation

Chemical Name | Oleic Acid |

Other Name | 9-cis-Octadecenoicacid; 9-Octadecenoic acid, cis-; 9Octadecenoicacid(9Z); Oleic oil; High oleic oil |

CAS | 112-80-1 |

EINECS | 204-007-1 |

Type | Food additives; Pharmaceutical raw materials; Organic raw materials; Plant extracts; Chemical additives |

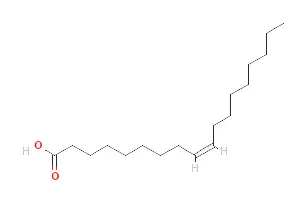

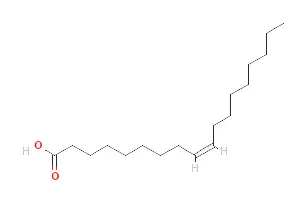

Molecular Formula | C18H34O2 |

Molecular Weight | 282.46 |

Oleic Acid Properties

Melting point | 13-14 °C(lit.) |

Boiling point | 360 °C |

density | 0.89 g/mL at 25 °C(lit.) |

vapor density | 1.03 (vs air) |

vapor pressure | 52 mm Hg ( 37 °C) |

refractive index | n20/D 1.377 |

Fp | 133 °F |

storage temp. | -20°C |

solubility | Miscible with ethanol, ether, acetone, chloroform, dimethyl formamide and dimethyl sulfoxide. |

form | Liquid |

pka | pKa 5.35(H2O,t =25) (Uncertain) |

Specific Gravity | 0.892 (20/4℃) |

color | Colorless to pale yellow |

Odor | Peculiar Lard-Like |

Water Solubility | negligible |

Sensitive | Air Sensitive |

What is Oleic Acid?

Oleic acid, as a monounsaturated -9 fatty acid, is widely distributed in plants and animals in nature. It presents itself in a pure form as a slightly anemic pale yellow oily liquid, exuding a faint, distinctive aroma of animal or vegetable oils. As time goes by and it comes into contact with air, its color will gradually deepen, while the common oleic acid products in the commercial market appear as yellow to red oily liquids with a specific smell similar to lard. This substance is usually extracted from vegetable oil soap as raw material through a series of fine chemical processes such as saponification, acid hydrolysis, water washing, vacuum distillation and cold pressing.

In nature, oleic acid is mainly abundant in various pet oils and certain vegetable oils in the form of triglycerides. Especially oleic acid directly obtained from natural sources is widely used in multiple fields such as the textile industry, leather processing, cosmetic manufacturing, and the pharmaceutical industry. For example, adding a small amount of oleic acid to fabric softener can enhance the hand feel of the fabric. Adding it to high-end skin care products can enhance the moisturizing effect and promote skin health. In the production of medicines, it is also an indispensable part of many drug formulas.

In addition to the above applications, recent studies have also found that oleic acid has many benefits for human health. Moderate intake of oleic acid can help lower cholesterol levels (including harmful low-density lipoprotein) and triglyceride content in the blood, thereby protecting the cardiovascular system. In addition, it can also help relieve the pain of arthritis patients, enhance brain function, improve emotional state, reduce anxiety symptoms, and even has a certain effect on preventing migraine attacks. Long-term use of products rich in oleic acid can also keep the skin youthful, maintain a good metabolic balance, and help control blood sugar levels, thereby preventing the occurrence of diabetes to a certain extent.

More importantly, scientists have confirmed that oleic acid has powerful antioxidant properties, which can effectively prevent "bad" cholesterol from oxidizing and deteriorating to form plaques that clog blood vessels, thereby significantly reducing the risk of heart disease. At the same time, because it can eliminate excessive free radicals in the body and activate the vitality of the immune system, it is also believed to help inhibit tumor growth and reduce the incidence of cancer. In conclusion, whether in daily diet or professional medical fields, the rational utilization of oleic acid has demonstrated great potential.

Oleic Acid Uses

1. Recommended materials for biochemical evaluation and gas chromatography

In today's complex and diverse scientific research fields, for biochemical evaluation and gas chromatography analysis, choosing appropriate materials is a key link to ensure the accuracy and reliability of experimental results. These materials need to possess a series of specific properties, such as good chemical stability, low background interference, and appropriate interaction with the substance to be tested. Different biochemical evaluations and gas chromatography application scenarios have different requirements for materials. Therefore, researchers need to carefully select appropriate materials based on specific experimental purposes and sample characteristics. Some common materials include compounds with high purity and specific functional groups, which can accurately simulate the internal environment of organisms during biochemical reactions and provide reliable data support for biochemical evaluations. Meanwhile, in gas chromatography analysis, appropriate stationary phase materials can effectively separate and detect various complex mixtures, ensuring the accuracy and sensitivity of the analysis results.

Ii. The Wide Application of Oleic acid

(1) Applications in the industrial field

Oleic acid, a plastic plasticizer, plays a crucial role in industrial production and is one of the key raw materials for the preparation of plastic plasticizers. Through specific chemical reactions and technological processes, oleic acid can interact with other chemical substances to form plasticizers with good flexibility and plasticity. These plasticizers are widely used in the production of various plastic products, such as packaging materials and the outer sheaths of wires and cables, which can enhance the flexibility and processing performance of plastic products, making them more in line with the demands of different industries.

As an important chemical raw material, oleic acid can be used to produce chemical emulsifiers. In many industrial production processes, such as petrochemicals and textile printing and dyeing, it is necessary to evenly mix immiscible substances together. At this time, emulsifiers are needed. After a series of chemical reactions and treatments, oleic acid can form emulsifiers with good emulsifying effects, helping to achieve uniform dispersion and stable mixing among different substances, and improving production efficiency and product quality.

Oleic acid, a component of lubricating oil, is also one of the important components of lubricating oil. During the operation of mechanical equipment, lubricating oil plays a crucial role in reducing friction, lowering wear, dissipating heat and preventing corrosion. Oleic acid has excellent lubricating and antioxidant properties. It can provide effective lubrication protection for mechanical components under different working conditions, extend the service life of equipment, and improve the operational efficiency of equipment.

In the detergent industry, oleic acid also plays an indispensable role as a raw material for the production of detergents. It can be used as one of the main components of detergents and participate in the formula design of detergents. Oleic acid has excellent decontamination ability and emulsifying performance, which can effectively remove various stains and oils, keeping clothes, tableware and other items clean and hygienic. In addition, oleic acid can also be compounded with other surfactants to further enhance the performance and quality of the detergent.

In the mining industry, oleic acid can be used as a representative agent for ore flotation. Ore flotation is an important mineral processing method. By adding specific flotation reagents to the pulp, useful minerals are separated from gangue minerals, thereby achieving the purpose of enriching useful minerals. Oleic acid, as a flotation reagent, can selectively adsorb on the surface of useful minerals, changing the physical and chemical properties of the mineral surface to make it floatable, while gangue minerals remain in the pulp, thereby achieving effective separation and purification of useful minerals.

(II) Application in the Food Industry

Oleic acid has a wide range of applications in baked goods. It can serve as part of the dough conditioner, regulating the rheological properties of the dough to enhance its elasticity and extensibility, thereby increasing the volume and texture of baked goods. In addition, oleic acid can also play a certain role in preservation during the baking process, extending the shelf life of baked goods.

In the processing of meat products, oleic acid can be used as a preservative and flavor enhancer. It can form a protective film on the surface of meat, preventing water loss and microbial contamination, and maintaining the tenderness and taste of the meat. Meanwhile, oleic acid can also interact with other components in meat to produce unique flavor substances, enhancing the flavor quality of meat products.

Oleic acid is also widely used in the production of condiments. It can serve as one of the basic raw materials for seasonings, providing unique flavors and textures for condiments. For instance, in some compound seasonings, oleic acid can be combined with other spices and flavoring ingredients to create a rich variety of flavors, meeting the needs of different consumers.

(3) Applications in daily chemical and other industrial fields

Oleic acid, the basic raw material for detergent and grease soap bases, is an important basic raw material for detergent and grease soap bases. In the production of detergents, oleic acid, through saponification reaction, can generate fatty acid salts, the main components of soap, which have excellent decontamination ability and foaming performance. In the production of oil soap bases, oleic acid is one of the key components, which can provide good lubricity and moisture retention for oil soap bases, making them widely used in cosmetics, skin care products and other fields.

In the cosmetics industry, oleic acid is widely used as a basic raw material. It can be added to cosmetics as an emollient, emulsifier and other ingredients to provide moisturizing and hydrating effects for the skin, while helping other ingredients in cosmetics to be better dispersed and absorbed. Oleic acid also has certain antioxidant properties, which can delay skin aging and protect the skin from the damage of free radicals.

Oleic acid, a basic raw material for chemical fiber oil and fabric auxiliaries, is also one of the important basic raw materials for chemical fiber oil and fabric auxiliaries. In the production process of chemical fibers, oleic acid can be used as a lubricant and antistatic agent, reducing the friction between fibers and the generation of static electricity, and improving the quality and performance of chemical fiber products. During the fabric finishing process, oleic acid can serve as a key component of fabric softeners and water repellents, endowing the fabric with properties such as softness, smoothness, and water resistance, thereby enhancing the fabric's usability and comfort.

The application of fine-tuning oleic acid in the production of engineering plastics and nylon Fine-tuning oleic acid plays an important role in the production of plastics, engineering plastics, nylon 8 and nylon 9. It can be used as a raw material to participate in the polymerization reaction, influencing the molecular structure and properties of the polymer. By adjusting the dosage of oleic acid and the reaction conditions, the performance of plastic and nylon products, such as strength, toughness, and heat resistance, can be precisely controlled to meet the demands of different fields for high-performance materials.

(4) Special uses and derivative applications

Lubricant and unclogging agent

Oleic acid can not only serve as a lubricant but also act as a unclogging agent that penetrates mud. In some industries such as drilling and oil extraction, oleic acid can be injected into the wellbore or pipeline to reduce the frictional resistance between the drilling tools and the wellbore and improve the drilling efficiency. At the same time, when problems such as mud blockage occur, oleic acid can penetrate into the mud, change the rheological properties of the mud, make it easier to remove, and restore the smoothness of the pipeline.

The application of oleate or potassium salt

Oleate or potassium salt is one of the effective components of soap. During the soap production process, oleic acid undergoes saponification with alkali to form oleate. This oleate has excellent decontamination ability and foaming performance, and can effectively remove dirt and oil from the skin surface.

The characteristics and applications of pure oleic acid: Pure oleic acid has excellent decontamination properties and can be used as emulsifiers and other surfactants. In industrial production and daily life, pure oleic acid is widely used in various cleaning and emulsification processes, such as metal cleaning and emulsion preparation. In addition, pure oleic acid can also be used to treat cholelithiasis. Its specific mechanism of action is to promote the dissolution and excretion of gallstones by altering the composition and physicochemical properties of bile.

The various other metal salts of oleic acid can also be used in waterproof fabrics, lubricants, polishes and other fields. For instance, certain metal salts can combine with fabric fibers to form a waterproof layer, enhancing the waterproof performance of the fabric. Adding an appropriate amount of oleic acid metal salts to the lubricant can improve the lubrication effect. In polishing agents, oleic acid metal salts can play a role in grinding and polishing, making the surface of objects smoother and flatter. In addition, the barium salt of oleic acid can be used as a rodenticide. It has certain toxicity and rodenticidal effects, and can effectively control rodent damage.

Preparation of plastic plasticizers butyl epoxy oleate and octyl epoxy oleate

Oleic acid is mainly used in the preparation of plastic plasticizers butyl epoxy oleate and octyl epoxy oleate. These two plasticizers have good compatibility, durability and safety, and are widely used in the production of plastic products. Through specific synthetic processes, oleic acid can be transformed into butyl epoxy oleate and octyl epoxy oleate, providing excellent plasticizing performance for plastic products, making them softer, more durable and easier to process.

Applications in the woolen textile market

In the woolen textile market, oleic acid is mainly used in the formulation of antistatic agents and as a lubricating softener. During the wool textile process, due to the inherent electrostatic properties of wool fibers, problems such as fiber entanglement and difficulty in carding are prone to occur. Oleic acid, as an antistatic agent, can effectively eliminate static electricity on the surface of wool fibers, making them smoother and facilitating processing and production. Meanwhile, oleic acid can also serve as a lubricating and softening agent, reducing the friction between wool fibers and enhancing the quality and hand feel of wool textiles.

Applications in the wood industry

In the wood industry, oleic acid is used to prepare the representative paraffin emulsion for water resistance. Wood is prone to erosion by moisture during use, leading to problems such as deformation and decay. By mixing oleic acid with other components to prepare paraffin emulsion and applying it to the surface of wood, a waterproof protective film can be formed to prevent water from penetrating into the interior of the wood and extend its service life.

The related applications of azelaic acid

The preparation method: Azelaic acid can be prepared by the oxidation method. This method usually uses specific organic compounds as raw materials and conducts oxidation reactions under certain reaction conditions to generate azelaic acid. Oxidation method has the advantages of relatively mild reaction conditions and high product purity, and is suitable for large-scale industrial production.

Azelaic acid is one of the important raw materials for preparing polyamide resin in the production of polyamide resin. Polyamide resin has excellent mechanical properties, wear resistance, chemical corrosion resistance and other advantages, and is widely used in the textile, plastic, rubber and other industries. Azelaic acid can be used to prepare polyamide resins of different types and properties through polycondensation reactions with other monomers, meeting the demands of various fields.

In other application fields, azelaic acid can also be used to manufacture water repellents, lubricants, fabric lubricants, etc. In the field of building materials, azelaic acid can be used as a component of waterproofing agents to enhance the waterproof performance of buildings. In the mechanical manufacturing and textile industries, azelaic acid can be used as a lubricant and fabric lubricant to reduce friction and wear, and improve production efficiency and product quality. In addition, azelaic acid can also be used to prepare various products such as input and release agents, ballpoint pen ink, and carbon paper, providing convenience for People's Daily life and work.