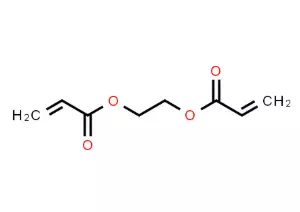

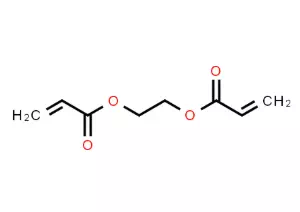

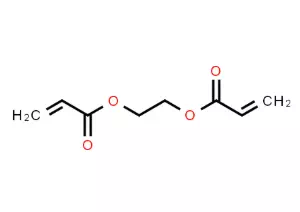

What is Poly(ethylene glycol) diacrylate CAS 26570-48-9?

Polyethylene glycol diacrylate (PEGDA), as a derivative of polyethylene glycol, is an important environmentally friendly polymer material with good biocompatibility and degradability. It is used as an auxiliary agent (such as reaction medium, carrier or modifier) in catalytic systems, or as a key component in fields such as photopolymerization and biomaterials.

Poly(ethylene glycol) diacrylate CAS 26570-48-9 Use

I、 Application as a catalyst aid (indirectly involved in catalytic systems)

PEGDA mainly plays an auxiliary role in catalytic reactions through the following ways:

Fixed enzyme/catalyst:

The porous structure and hydrophilicity of PEGDA hydrogel can wrap the enzyme or metal catalyst to improve its stability and reusability (for example, the transesterification reaction catalyzed by fixed lipase to produce biodiesel).

II、 Core application as functional monomer/crosslinking agent (direct use)

1. In the field of UV curable materials (leading applications)

UV curable coatings/inks:

As an active diluent and crosslinking agent, it reduces the viscosity of the system, endows the coating with flexibility, wear resistance, and adhesion after curing (used in wood coatings, metal coatings, printing inks).

3D printing photosensitive resin:

In SLA/DLP technology, as the main resin, the hardness and elasticity after curing (such as flexible devices and medical models) are controlled by adjusting the molecular weight of PEGDA (such as PEG200DA, PEG400DA).

Photoresist:

The graphic technology used in microelectronic processing has high resolution characteristics suitable for preparing precision circuits.

2. Biomedical field

Hydrogel drug carrier:

PEGDA cross-linked network is used to package drugs and achieve pH/temperature responsive release (such as targeted delivery of anticancer drugs).

Organizational engineering support:

UV curing preparation of biomimetic scaffolds to support cell growth (such as cartilage repair and skin regeneration).

Medical dressings:

The super absorbent hydrogel covers the wound, maintains a humid environment and sustains the release of antibacterial ingredients.

3. Modification of high-performance materials

Polymer reinforcement:

As a crosslinking agent, acrylic resin, polyurethane, etc. are added to enhance water resistance and mechanical strength.

Anti pollution coating:

Preparation of anti protein adsorption coatings using the hydrophilicity of PEG chains (such as medical devices and ship anti fouling).

Poly(ethylene glycol) diacrylate CAS 26570-48-9 safety

Safe operation:

Liquid PEGDA is irritating to the skin/eyes and requires protective equipment.

Storage conditions:

Avoid light and refrigerate, add polymerization inhibitors (such as MEHQ) to prevent self aggregation.

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.