What is polylactic acid CAS 26100-51-6?

Polylactic acid (PLA) is indeed a highly regarded bio-based and renewable biodegradable material. It originates from plants and eventually returns to nature, providing a promising green solution to reduce our reliance on petroleum resources and address the problem of "white pollution".

The emergence of polylactic acid is a clever process of "transforming waste into treasure" or "converting food resources into valuable materials". It mainly uses plant resources rich in starch such as corn, cassava, and sugar cane as raw materials. The core preparation process can be summarized as the following steps:

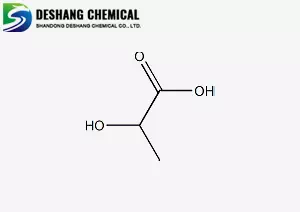

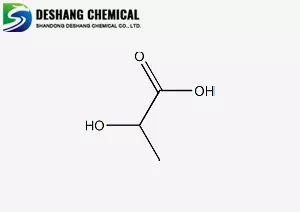

Sugarification and Fermentation: Starch extracted from plants undergoes the sugarification process to convert into glucose. This glucose is then fermented by specific microorganisms (such as lactic acid bacteria) to produce high-purity lactic acid monomers.

Polymerization: Lactic acid molecules are chemically polymerized to form high-molecular-weight polylactic acid. Currently, the most common industrial method is the ring-opening polymerization of lactide. This method allows for better control of the polymer's molecular weight, resulting in polylactic acid with superior performance.

polylactic acid CAS 26100-51-6 Use

Polylactic acid (PLA) is derived from crops such as corn and cassava. It is produced by microbial fermentation and extraction from lactic acid, and then undergoes refining, dehydration oligomerization, high-temperature cracking, and polymerization. PLA has excellent biodegradability. After being discarded, it can be completely degraded by microorganisms in the soil within one year, generating CO2 and water, and causing no pollution to the environment. PLA itself is a fatty acid-based polyester and possesses the basic characteristics of common polymer materials, with good mechanical processing properties, low shrinkage rate, and the ability to fulfill the functions of most synthetic plastics. It is widely used in the production of packaging materials, disposable tableware, home appliance shells, fibers, 3D consumables, etc.

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.