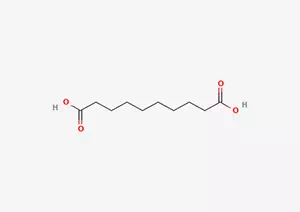

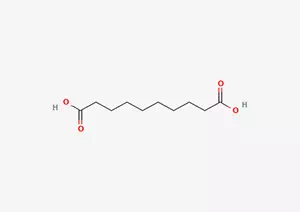

What is Sebacic acid CAS 111-20-6?

In today complex and diverse field of chemical engineering, sebacic acid (with the corresponding CAS number 111-20-6) is like a brilliant pearl. As a typical representative of long-chain dicarboxylic acids, it emits a unique and dazzling light. The series of outstanding characteristics it possesses have enabled it to demonstrate an irreplaceable and significant role in numerous key fields.

In the field of polymers, sebacic acid, with its unique molecular structure and chemical properties, has become an indispensable key raw material in the synthesis process of many high-performance polymers. It can precisely react with other monomers and, through complex chemical bonding processes, construct polymer materials with specific properties and functions. These polymer materials play a crucial role in high-end industries such as aerospace, automotive manufacturing, and electronics and electrical appliances. For instance, they are used to produce engineering plastics with high strength and high-temperature resistance, as well as special rubbers with excellent insulation performance and flexibility.

In the field of plasticizers, sebacic acid also plays a crucial role. As people pay increasing attention to environmental protection and health, the environmental and health problems brought about by traditional plasticizers have gradually drawn attention. Sebacic acid, with its excellent plasticizing effect and relatively low environmental hazard, has become an important basis for the research and application of environmentally friendly plasticizers. It can effectively enhance the flexibility and ductility of plastic materials, while reducing the release of harmful substances during the processing and use of plastics, providing strong support for the sustainable development of plastic products.

The medical field is also an important stage where sebacic acid can shine. Due to its special chemical properties and biocompatibility, sebacic acid has extensive applications in drug synthesis and formulation processes. It can serve as an important component of drug molecules, participate in the construction of complex drug structures, and enhance the efficacy and stability of drugs. Meanwhile, in the research and development of some new drug delivery systems, sebacic acid is also used as a key excipient to help drugs achieve precise and controllable release, thereby enhancing the safety and effectiveness of drug treatment.

Sebacic acid can occupy such an important position in many fields not only because of its wide application, but also due to a series of excellent properties it possesses. Among them, cold resistance is a prominent feature of sebacic acid. In low-temperature environments, the properties of many chemical substances will be affected, and even phenomena such as solidification and crystallization may occur, thereby leading to a decline in the performance of related materials and products. However, sebacic acid can maintain good fluidity and chemical stability at extremely low temperatures, which gives it a significant advantage in some application scenarios with high requirements for low-temperature performance. For instance, in outdoor equipment in cold regions, low-temperature storage materials, and certain industrial production processes under special working conditions, the presence of sebacic acid can ensure the normal operation of related products.

Chemical stability is another significant advantage of sebacic acid. Under various complex chemical reaction environments and harsh usage conditions, sebacic acid can maintain the integrity of its molecular structure and the relative stability of its chemical properties. It is not prone to unnecessary chemical reactions with other substances, thus ensuring reliability and safety during industrial production and use. This chemical stability makes sebacic acid less prone to deterioration during long-term storage and transportation, providing a solid guarantee for its wide application.

It is worth mentioning that with the continuous enhancement of environmental awareness and the deep-rooted concept of green chemistry, the production process of sebacic acid is also constantly being improved and optimized. Researchers are committed to developing more environmentally friendly and efficient production methods to reduce energy consumption and pollutant emissions during the production process. By adopting advanced catalytic technologies, green solvents and optimizing reaction conditions, the production process of sebacic acid is gradually moving towards a green and sustainable direction. This not only meets the requirements of modern society for environmental protection, but also lays a solid foundation for the long-term development of the sebacic acid industry.

From the perspective of market data, the significance and development prospects of sebacic acid have been fully confirmed. In recent years, with the rapid development of the nylon and polyurethane industries, the demand for sebacic acid has shown a continuous upward trend. Nylon, as an important engineering plastic, is widely used in many fields such as automobiles, electronics and machinery. In the production process of nylon, sebacic acid, as one of the important raw materials, can endow nylon products with excellent properties, such as good strength, wear resistance and heat resistance, etc. Similarly, polyurethane, as an excellent polymer material, has extensive applications in fields such as construction, furniture, and automotive interiors. Sebacic acid also plays a key role in the synthesis of polyurethane, which can enhance the flexibility, weather resistance and chemical corrosion resistance of polyurethane products.

Especially in the field of environmentally friendly plasticizers, sebacic acid has huge market potential. With the increasing global restrictions on traditional plasticizers and the growing demand for alternatives, the market size of environmentally friendly plasticizers is constantly expanding. Sebacic acid, as an ideal raw material for environmentally friendly plasticizers, has attracted extensive attention and favor from the market due to its excellent performance and relatively low environmental risks. More and more enterprises have begun to increase their investment in the research and development and application of sebacic acid in the field of environmentally friendly plasticizers, which has further driven the growth of the market demand for sebacic acid. It can be foreseen that in the future chemical market, sebacic acid will continue to play an irreplaceable role, providing strong support for the development of polymers, plasticizers, pharmaceuticals and other fields. At the same time, it will also take more solid steps on the road of green chemistry and sustainable development.

Sebacic acid CAS 111-20-6 Use

Polymers and engineering plastics

Nylon series:

It is used for synthesizing polyamide resins such as nylon 1010, nylon 610, nylon 810 and nylon 9, and is widely applied in mechanical parts, gears, high-temperature resistant materials and other fields.

Polyurethane material

As a raw material for polyester polyols, it is used to prepare polyurethane elastomers, adhesives and foam plastics with excellent hydrolysis resistance.

2. Plasticizers and solvents

Cold-resistant plasticizers: Produce dioctyl sebacate (DOS) and dibutyl sebacate (DBS), which are used in PVC plastic products (such as cables and artificial leather) to enhance low-temperature flexibility.

Lubricants and softeners: Used in high-temperature lubricating oil and synthetic grease to extend the service life of machinery.

3. Medicine and Chemical Engineering

Drug intermediates: Used in the synthesis of anti-ulcer drugs (such as Gastron) and pharmaceutical excipients.

Antioxidants and additives: They are used in the chemical industry as curing agents for epoxy resins, stabilizers for coatings, and raw materials for the synthesis of fragrances.

4. Other industrial applications

Electroplating and metal treatment: Replace cyanide in electroplating solutions to reduce pollution.

Food packaging materials: As an additive for polymer materials, it enhances the performance of plastics.

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.