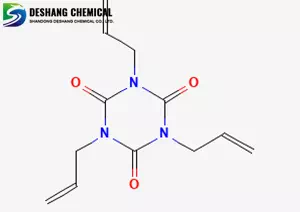

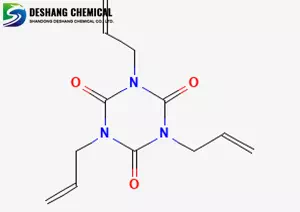

What is TAIC Triallyl Isocyanurate CAS 1025-15-6?

Triallyl isocyanurate (TAIC), as an efficient crosslinking agent, has seen a continuous increase in demand in the fields of new energy materials (such as EVA film), special rubber, and electronic packaging. Its low toxicity, multi-functionality and mature supply chain make it a key additive for polymer modification. When purchasing, pay attention to the purity (≥98%) and the type of stabilizer, and strictly follow the safety storage regulations.

TAIC Triallyl Isocyanurate CAS 1025-15-6 Use

1.Crosslinking modification of polymer materials

Plastics: Used for thermal crosslinking or irradiation crosslinking of polyethylene (PE), polyvinyl chloride (PVC), EVA, etc., to enhance heat resistance, mechanical strength and electrical properties, with an addition amount of 1-3%

Rubber: As a vulcanizing aid for ethylene propylene rubber and fluorine rubber, when used in combination with peroxides (such as DCP), it can shorten the vulcanization time and enhance wear resistance (dosage: 0.5% to 4%).

2.Synthesis of special resins

Ion exchange resin: Replace divinylbenzene to prepare high-temperature resistant and anti-pollution resin

Unsaturated polyester: Enhances the heat resistance of fiberglass reinforced plastic products to over 180℃

3.New energy and electronic materials

Solar cells: The TATIC-S type is specifically designed for EVA encapsulation film to enhance weather resistance

Printed circuit boards: Prepolymers are coated on the metal surface to provide a radiation-resistant insulating layer

4.Other fields

Uv-curable coatings, flame retardant intermediates, acrylic glass modifiers and safety glass adhesives

TAIC Triallyl Isocyanurate CAS 1025-15-6 safety

Danger

Swallowing is harmful (H302) and may irritate the respiratory tract and skin

It may polymerize at high temperatures, so contact with peroxides, strong acids/bases should be avoided

Protective measures

Wear protective gloves, goggles and dust masks when operating, and ensure good ventilation

Storage requirements

Store in a sealed, light-proof container in a cool place below 25°C. Transport as non-hazardous goods and avoid exposure to direct sunlight

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.