What is Tetraacetylethylenediamine CAS 10543-57-4?

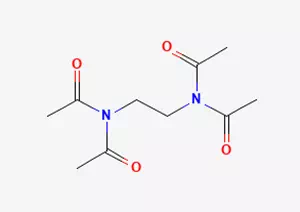

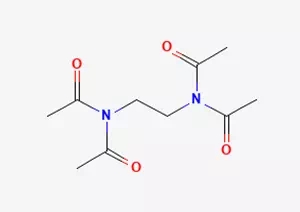

Chemical Name: Tetraacetyl ethylenediamine (Also known as TAED, tetraacetyl ethylenediamine)

Molecular formula: C₁₀H₁₆N₂O₄

Molecular weight: 228.25 g/mol

CAS Number: 10543-57-4

EINECS number: 234-123-8

Appearance: Grayish-white to cream-colored crystalline powder or colored granules (white/blue/green), with a slight acetic acid smell

Application scenario optimization

Washing industry: Select industrial grade (92-94% purity, cost ≤50 yuan /kg), and compound with sodium percarbonate to enhance the low-temperature bleaching effect.

Pharmaceutical synthesis: Use ≥99% HPLC grade to control heavy metal residues (Pb≤1 ppm).

Purchasing Notes:

Request the MSDS and heavy metal test report. For colored particles, the safety of the dye needs to be confirmed.

Trend Outlook

Green transformation: The substitution of bio-based raw materials (such as plant derivatives) may become a future focus.

Tetraacetylethylenediamine CAS 10543-57-4 Use

Detergent bleaching activator (dominant application, accounting for more than 70% of the demand)

Low-temperature bleaching: When compounded with sodium percarbonate/sodium perborate, peracetic acid is released at 30-60 ℃, enhancing the bleaching efficiency (three times higher than peroxides alone).

Energy conservation and environmental protection: Reduce the bleaching temperature to room temperature to decrease energy consumption; The reaction products are biodegradable and leave no chlorine residue (80% of bleaching detergents in Europe use the TAED system).

Compatibility: Compatible with enzyme preparations and surfactants, without damaging fabric fibers.

The fields of industry and environmental protection

Wastewater treatment: Decompose organic pollutants and remove heavy metal ions (such as lead and cadmium).

Gas drying: As a desiccant, it controls the humidity of industrial gases.

Pharmaceutical intermediates: Synthetic antibiotics and anti-cancer drugs (with a purity grade of ≥99%).

Emerging applications

Disinfection and sterilization: It generates peracetic acid to kill bacteria/viruses and is used in sewer unclogging agents and disinfection of medical devices.

Agricultural regulators: Enhance the stress resistance of crops and reduce pesticide residues.

Tetraacetylethylenediamine CAS 10543-57-4 safety

Health risk:

It is irritating to the skin and eyes (R36/37/38). A gas mask and acid and alkali resistant gloves are required for operation.

Inhalation of dust may cause respiratory tract inflammation (Safety term: S22-S24/25).

Storage requirements:

Keep sealed and away from light. Store in a cool and dry place at ≤25℃, with a relative humidity of less than 75%.

Environmental protection compliance

Exports to the European Union require REACH certification, and food/pharmaceutical grades need to comply with the FDA/GB 2760 standard.

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.