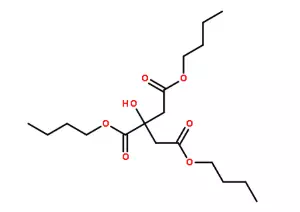

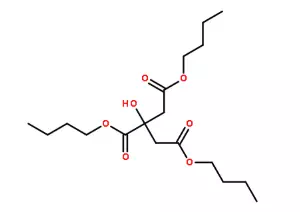

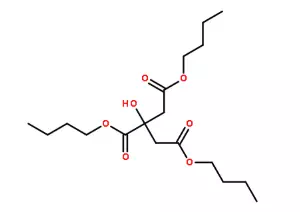

What is Tributyl citrate CAS 77-94-1?

Tributyl Citrate (TBC) is a non-toxic, fruity, colorless, transparent oily liquid at room temperature. It is a very important organic ester compound, which is widely used in many industrial fields mainly for its excellent plasticizing properties and outstanding safety and environmental protection characteristics.

Tributyl citrate CAS 77-94-1 Use

I.As the main plasticizer of polyvinyl chloride (PVC):

Core function: This is the main use of TBC. It can effectively insert between PVC polymer chains, weaken the force between molecular chains, increase the mobility of chain segments, thereby significantly improving the flexibility, ductility and low-temperature performance of PVC, and reducing its glass transition temperature (making the plastic less brittle at low temperatures).

Application areas:

Food packaging materials: Used to manufacture food-grade cling film, twist film, beverage bottle cap gaskets, etc. TBC is approved by authoritative agencies such as the US FDA and the European Union for use in food contact materials, and has high safety.

Medical devices: Manufacture of disposable infusion tubes, blood bags, respiratory masks, gloves and other medical soft PVC products. Its non-toxicity, low migration and good biocompatibility are key advantages.

Children's toys and care products: such as toys, chewing gum, shower curtains, tablecloths, etc. TBC does not contain phthalates (traditional plasticizers that pose health risks), complies with increasingly stringent environmental and safety regulations (such as EU REACH regulations, RoHS directives, US Consumer Product Safety Improvement Act CPSIA, etc.), and is an ideal choice to replace phthalates plasticizers (such as DOP/DEHP).

Artificial leather and synthetic leather: used in automotive interiors, furniture, bags, shoes, etc., providing good feel and durability.

Films and sheets: such as agricultural films, industrial films, decorative sheets, etc.

Wire and cable insulation and sheathing: Provide the required softness and electrical insulation properties.

II.As a plasticizer for cellulose resins (such as nitrocellulose, cellulose acetate, ethyl cellulose):

Function: TBC can improve the processing properties of cellulose plastics (such as reducing melt viscosity) and give them better flexibility, impact resistance and transparency.

Application areas:

Coatings and inks: Especially used in nitrocellulose paints (such as wood paint, car repair paint, leather paint, nail polish). TBC can provide good film-forming properties, gloss, adhesion, good solvent release and low odor.

Films and sheets: Such as cellulose acetate film (used in photographic film, packaging, etc.).

III.As a plasticizer/softener for synthetic rubber (such as nitrile rubber NBR, chloroprene rubber CR):

Function: Improve the processing fluidity of rubber (mixing, calendering, extrusion), reduce Mooney viscosity; improve the low-temperature flexibility, elasticity and cold resistance of vulcanized rubber; sometimes also play a role in reducing hardness.

Application areas: Manufacture of various rubber products, such as seals, gaskets, hoses, soles, etc.

IV.Application in adhesives:

Function: Used as a plasticizer in adhesives such as polyvinyl acetate (PVAc), acrylates, chloroprene rubber, etc., to improve the flexibility, initial adhesion and durability of the adhesive layer and improve low-temperature performance.

V.Other special uses:

Lubricant component: In specific lubricant formulations, using its lubricity and biodegradability.

Defoamer: Used as a defoamer component in specific industrial processes.

Special solvent: Dissolves certain natural resins and synthetic resins.

Tributyl citrate CAS 77-94-1 safety

Tributyl citrate (TBC) is an indispensable key additive in modern industry, especially in fields with extremely high requirements for safety and environmental protection (such as food contact materials, medical devices, children's products, and cosmetics). It is a mainstream solution to replace traditional toxic and harmful plasticizers.

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.