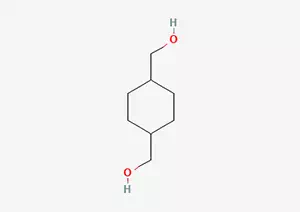

1,4-Cyclohexanedimethanol CAS 105-08-8 Uses

1, 4-cyclohexadimethanol (CHDM), as an important organic compound, has demonstrated outstanding performance characteristics in numerous fields. It has many remarkable characteristics, among which the glass transition temperature is relatively high. This characteristic makes it have unique application value in the field of materials science. It has good flexibility and can maintain the integrity of its structure under certain external forces, and is not prone to breakage or deformation. At the same time, its hardness is also quite excellent, providing a good basic support for the molding and processing of the material.

From the perspective of chemical properties, 1, 4-cyclohexadimethanol has excellent thermal stability. It can maintain a relatively stable chemical structure and physical properties even in high-temperature environments, and is not prone to decomposition or other chemical reactions. This provides a reliable guarantee for its application in high-temperature processing and some scenarios with high temperature requirements. It has good solubility and can be fully mixed with various solvents, which enables it to better come into contact and react with other substances during chemical reactions, thereby enhancing the efficiency and uniformity of the reactions. In addition, it also has excellent weather resistance. Whether under long-term natural environmental conditions such as sunlight, wind, and rain, or in complex climatic conditions, it can maintain the stability of its performance and is not prone to aging, fading, cracking and other phenomena.

In the synthesis of polyester compounds, 1, 4-cyclohexadimethanol plays a crucial role. It can significantly enhance the reactivity of polyester compounds, enabling the chemical reactions of polyester compounds to occur more rapidly and efficiently during the synthesis process, shortening the reaction time and improving production efficiency. At the same time, it can also enhance the hydrolytic stability of polyester compounds, enabling them to maintain the stability of their chemical structure when exposed to water or other humid environments, and be less likely to undergo hydrolysis reactions, thereby extending the service life of polyester compounds. In addition to enhancing the performance of polyester compounds themselves, 1, 4-cyclohexadimethanol can also improve the plasticity, gloss, transparency, printability and processability of polyester compounds in many aspects. It can make polyester compounds easier to form during the processing, achieve better surface gloss and transparency, improve the printing effect, and maintain good performance under various processing techniques.

In practical applications, 1, 4-cyclohexadimethanol has a wide range of uses. It is one of the important raw materials for synthesizing PETG. Through interaction with other chemical substances, PETG materials with excellent performance can be prepared. Meanwhile, it also serves as an intermediate for the production of saturated and unsaturated polymers for coatings, adhesives, insulating materials and other special applications, providing crucial support for the performance improvement of products in these fields.

Specifically, in the manufacturing of polyester fibers, 1, 4-cyclohexadimethanol can endow the fibers with better flexibility, strength and durability, enabling the polyester fibers produced to have higher quality and wider applications in the textile industry. In the manufacturing of polyester electrical appliances, it can enhance the insulation performance and heat resistance of the appliances, ensuring their safety and stability during long-term use. For the synthesis of unsaturated polyester resins, 1, 4-cyclohexadimethanol can improve the performance of the resins, making their applications in composite materials, coatings and other fields more extensive. In the production of polyester glaze, it can enhance the gloss, hardness and weather resistance of the glaze surface, and improve the quality and appearance effect of the product. In addition, 1, 4-cyclohexadimethanol is also used in the production of lubricants and hydraulic oil, which can enhance the lubricating performance of lubricants and the anti-wear performance of hydraulic oil, and extend the service life of equipment.

It is worth mentioning that an important application of 1, 4-di (hydroxymethyl) cyclohexane is in the production of PET. During the production process of PET, even adding only a small amount of CHDM can significantly change the performance of PET. It can enhance the transparency of PET, making the produced PET materials clearer and more transparent, meeting some application scenarios with high transparency requirements, such as packaging materials and optical films. Meanwhile, CHDM can also lower the melting point of PET, enabling it to be processed at a lower temperature during the molding process. This not only reduces energy consumption but also lowers the formation of unwanted by-products, thereby enhancing production efficiency and product quality.

Because CHDM is a material rich in crystallinity, it enables polyester to have a higher glass transition temperature than linear ethylene glycol. This characteristic has enabled crystalline polyester to be widely used in the field of powder coatings. In automotive, train and bus coatings as well as general industrial coatings, the coatings prepared with the participation of CHDM have excellent adhesion, corrosion resistance and weather resistance, and can provide long-term and effective protection for the coated objects. In addition, CHDM is also used in the field of unsaturated polyester, such as gel coatings and glass fiber reinforced plastics. In gel coatings, it can enhance the hardness and wear resistance of the coating. In glass fiber reinforced plastics, it can enhance the strength and toughness of the plastics. The sheet forming compound is also made of CHDM. This compound has excellent forming performance and mechanical properties, and can meet the requirements of different sheet processing. High-performance polyurethane is made from polycarbonate diol derived from CHDM. This type of polyurethane features excellent elasticity, wear resistance and chemical corrosion resistance, and is widely used in the automotive, construction, aerospace and other fields. Radiation-cured coatings are formulated with alkoxylated CHDM acrylate. This type of coating can cure rapidly under the effect of radiation, forming a coating with toughness and flexibility, providing an ideal solution for some application scenarios with high requirements for curing speed and coating performance.