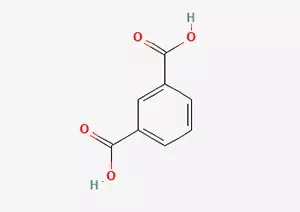

In today's rich and colorful chemical world, isophthalic acid, as an extremely important and widely used chemical raw material, is playing an indispensable role.

In the field of polyester, isophthalic acid has demonstrated its unique value. If isophthalic acid is copolymerized with PTA (purified terephthalic acid), a series of products with special properties can be produced, such as bottle flakes and low-melt cotton, etc. This copolymerization process is not a simple mixing but involves a series of complex and precise chemical reactions. During this process, the molecular structures of isophthalic acid and PTA are combined to form polymer chains with specific properties, thereby endowing the final product with unique physical and chemical characteristics, enabling it to meet the specific demands of various fields.

In addition to its application in the polyester field, isophthalic acid also holds an important position in the resin industry. When isophthalic acid is added to alkyd coating resins and unsaturated polyester resins, a series of wonderful chemical changes will be triggered. Specifically, the addition of isophthalic acid can significantly enhance the weather resistance of the resin. This characteristic makes the modified resin particularly suitable for the manufacturing of outdoor products. In outdoor environments, products need to withstand various harsh conditions, such as intense sunlight exposure, rain erosion, and temperature changes. The improved weather resistance brought by isophthalic acid is like covering the product with a solid "protective armor", enabling it to maintain long-term stability and excellent performance in outdoor environments and extend the product's service life.

Not only that, after sulfonation reaction of isophthalic acid, polyester fiber dyeing modifiers (three monomers) can also be obtained. This process is a typical chemical transformation reaction. Through sulfonation reaction, the molecular structure of isophthalic acid undergoes specific changes, thereby obtaining a dyeing modifier with unique functions. When this modifier copolymerizes with polyester, it will have a profound impact on the performance of the fiber. At this point, the fibers can be dyed with cationic dyes. Compared with traditional dyeing methods, the use of cationic dyes for dyeing has many advantages. For instance, the colors of dyed fabrics will be more vivid and eye-catching, and both the saturation and glossiness of the colors can be significantly enhanced. Meanwhile, it can also reduce the dyeing and finishing temperature. This not only helps to save energy and reduce production costs, but also can minimize the possible damage to fibers during the high-temperature dyeing and finishing process, further improving the quality of the products.

From a more macroscopic perspective, phthalic acid has extensive applications in the production of multiple resin varieties. In the production of unsaturated polyester resin, PET copolymer resin and alkyd resin, phthalic acid plays an important role. Among them, in the production of unsaturated polyester resin, the proportion of phthalic acid is approximately 38.6%. This resin has excellent mechanical properties and chemical stability, and is widely used in multiple fields such as construction, automobiles, and ships. In the production of PET copolymer resin, the proportion of phthalic acid is as high as 39.9%. PET copolymer resin is widely used in the manufacture of various products such as fibers, films and packaging materials due to its excellent physical properties and processing performance. In the production of alkyd resins, phthalic acid also accounts for 14.9% of the proportion. Alkyd resins have excellent adhesion and weather resistance, and are often used in fields such as coatings and paints. In addition, there are some other application fields, in which phthalic acid accounts for approximately 6.6%.

In addition to the common application fields mentioned above, isophthalic acid also has many other important uses. For example, it can be used as a raw material to prepare poly (allyl isophthalate) (DAIP) resin. During this preparation process, isophthalic acid reacts with other specific chemical substances to form DAIP resin with unique properties. This resin features excellent high-temperature resistance and good insulation performance, and is thus widely used in the manufacture of various precise, complex, and high-temperature resistant insulating components and impregnated laminated materials. In fields such as electronics and electrical engineering, the requirements for insulating materials are extremely high, and DAIP resin precisely meets these strict requirements, providing strong support for the development of related industries.

Isophthalic acid can also be used to prepare diethyl phthalate (DEIP). In the production process of toluene diisocyanate, DEIP plays a crucial role as a specialized solvent. It can be well compatible with toluene diisocyanate and other reactants, ensuring the smooth progress of the reaction and helping to control the reaction rate and the quality of the product.

In addition, isophthalic acid also plays an irreplaceable role in the preparation of polybenzimidazole. Polybenzimidazole can be synthesized from isophthalic acid as the raw material through a series of complex chemical reactions. This substance, as a high-performance adhesive, features outstanding bonding performance and high-temperature resistance. It can be widely applied to the bonding of metal materials such as aluminum alloy, stainless steel, metal honeycomb structure, polyimide film and silicon wafers. In these fields, the requirements for adhesives are extremely strict, needing to possess multiple properties such as high strength, high temperature resistance, and corrosion resistance. Polybenzimidazole precisely meets these requirements, ensuring a firm connection between various metal materials.

Isophthalic acid can also be used to prepare di (2-ethylhexyl) isophthalic acid esters. This substance is a colorless oily liquid plasticizer and has good compatibility with resins such as PVC, nitrocellulose, and polystyrene. In the plastic processing industry, the role of plasticizers is to enhance the flexibility and plasticity of plastics, making them easier to process and shape. Di (2-ethylhexyl) isophthalate, as a high-quality plasticizer, can effectively improve the performance of plastics and expand the application range of plastics.

In addition, isophthalic acid can also be used to prepare phenylenediamine, a raw material for light stabilizers with UV-blocking effects. In fields such as outdoor products and plastic products, exposure to ultraviolet rays often leads to a decline in material performance and aging. As an important raw material for light stabilizers, phenylene diamine can absorb and block ultraviolet rays, protect materials from ultraviolet damage and extend the service life of materials.

Finally, isophthalic acid can also be used to prepare isobenzoyl chloride. Isobaryl chloride is an important organic synthesis intermediate and the main raw material for the production of polyaromatic polymers such as poly (m-benzoyl isobarenediamine) (PMIA) and aramid. During the synthesis of these high-performance polymers, isobenzoyl chloride undergoes polymerization reactions with other monomers to form polymer materials with excellent properties such as high strength, high modulus, and high temperature resistance. These materials have extensive applications in aerospace, national defense, textile and other fields, and have made significant contributions to the development of modern science and technology.