Microcrystalline Cellulose CAS 9004-34-6 MCC Information

Chemical Name | Microcrystalline Cellulose |

Other Name | Cellulose microcrystalline; α-Cellulose |

CAS | 9004-34-6 |

EINECS | 232-674-9 |

Type | Food additives; Pharmaceutical raw materials; Organic raw materials; Inorganic salt; Daily chemicals |

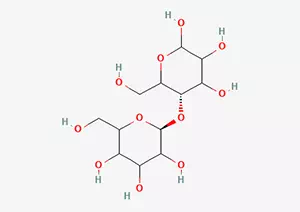

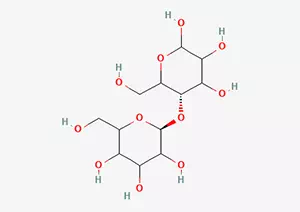

Molecular Formula | (C12H20O10)n |

Molecular Weight | 324.28 |

Microcrystalline Cellulose CAS 9004-34-6 MCC Properties

Melting point | 76-78 °C(Solv: acetone (67-64-1); chloroform (67-66-3)) |

density | 1.5 g/cm3 (20℃) |

refractive index | n20/D 1.504 |

Fp | 164 °C |

storage temp. | room temp |

solubility | Practically insoluble in water, in acetone, in anhydrous ethanol, in toluene, in dilute acids and in a 50 g/L solution of sodium hydroxide |

form | powder |

color | White or almost white |

Odor | Odorless |

PH | 5-7.5 (100g/l, H2O, 20℃)(slurry) |

Water Solubility | insoluble |

What is Microcrystalline Cellulose CAS 9004-34-6 MCC?

microcrystalline cellulose (MCC for short), as a derivative of natural cellulose processed through a fine acid hydrolysis process to a specific degree of polymerization, its unique physicochemical properties endow it with extensive application potential. This substance usually presents a pure white or nearly colorless appearance, without any odor or fragrance. Its particle size range spans a wide range from 2 microns to 80 microns, ensuring adaptability and flexibility in various application scenarios. One of the notable features of microcrystalline cellulose lies in its low density and excellent modulus properties, which enables it to effectively enhance the overall performance of the target material when used as a reinforcing agent for composite materials without significantly increasing the total weight of the material.

During the preparation process, the drying method of microcrystalline cellulose has a direct impact on its density: freeze-drying tends to produce products with lower density, while spray drying can obtain materials with higher density. This substance contains approximately 5% water in its natural state. This moderate water content is crucial for maintaining its stability. It is worth noting that although microcrystalline cellulose can be dispersed in water to form a uniform system, it is not truly soluble in water, nor is it soluble in dilute acids, most organic solvents and oily substances. However, in dilute alkaline solutions, it undergoes a process of expansion and partial dissolution, demonstrating a unique solubility behavior. When microcrystalline cellulose powder is mixed with water, it can form a white and transparent gel-like substance or paste. This form usually maintains long-term stability except for extremely thin layers, providing convenience for a variety of applications.

Microcrystalline cellulose plays a significant role in multiple fields, especially excelling in the pharmaceutical, food and cosmetic industries. In the field of medicine, it is not only an indispensable excipient in the preparation of pharmaceutical tablets, but also often used as a binder and disintegrant to improve the formability and release characteristics of drugs. In liquid drug preparations, it serves as a suspending agent to help maintain the uniform distribution of drug particles. In addition, in the food industry, microcrystalline cellulose, as a stabilizer and binder, is widely used in various products including beverages. It not only enhances the texture of the products but also serves as a fat substitute, contributing to the trend of healthy eating. In the cosmetics industry, it also plays the role of a stabilizer and processing aid, enhancing the stability and user experience of the product.

With the increasing emphasis on health and sustainability, microcrystalline cellulose is gradually becoming a favored choice in the pharmaceutical and food industries due to its high efficiency, renewability, biodegradability and wide availability. Its usage has been increasing year by year, which not only reflects the market's recognition but also indicates its positive role in improving product quality and promoting healthy consumption. As an excellent pharmaceutical excipient and food additive, microcrystalline cellulose shows great potential in enhancing drug dissolution, improving food flavor, reducing calorie intake and preventing obesity, and is an important force driving the innovative development of related industries.

Microcrystalline Cellulose CAS 9004-34-6 MCC Uses

Microcrystalline cellulose (MCC) has been officially approved in the European Union for use as a thickener, stabilizer or emulsifier, and has been assigned a specific E number, namely E460 (i). Alkaline cellulose, on the other hand, also has the E number E460, which indicates that they have a clear identity and application in food and related industrial applications.

In the field of cosmetics, MCC has demonstrated its versatile nature, capable of playing multiple roles such as abrasive, absorbent, and anti-caking agent. It can not only serve as a water-based tackifier to enhance the viscosity of the product, but also act as an adhesive to help components bond closely, or as a filler to adjust the texture of the product. In addition, MCC is often used as a stabilizer in detergents to ensure the stability of cosmetics. Meanwhile, it can also serve as a softening modifier and texture agent to enhance the touch and user experience of the product. These characteristics have enabled MCC to be widely applied in various hair care, skin care products and cosmetics.

MCC not only shines brightly in the cosmetics industry, but is also a highly valuable additive in other industries such as medicine and food. To ensure that MCC is suitable for these specific uses, precise measurements of its various properties are required. These properties include but are not limited to physical characteristics such as particle size, density level, compression index, Angle of repose, and powder porosity; And moisture-related properties such as hydration expansion capacity, moisture absorption capacity, and moisture content; There are also parameters such as crystallinity index and microcrystalline size that reflect its internal structure; Finally, it also includes mechanical properties such as hardness and tensile strength. These comprehensive measurements help ensure that the application of MCC in various fields can achieve the best results.

From a chemical perspective, microcrystalline cellulose is an edible glucose polymer that the human body cannot digest, and thus it is often used as a food additive. Vegetables, fruits and other foods in People's Daily diet all naturally contain fiber, while MCC provides a purer and more controllable source of fiber. In terms of regulating human physiological functions, MCC plays a significant role. It can promote intestinal peristalsis and effectively prevent digestive system diseases such as constipation. Furthermore, when ultrafine crystalline cellulose combines with water, it can form a colloid. This property makes it an ideal emulsifying thickener for food or cream. In the medical field, microcrystalline cellulose is a commonly used excipient for drugs. It can endow drugs with carrier functions, achieving sustained release and protection of drugs, thereby enhancing the efficacy and safety of drugs.

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.