Paraformaldehyde CAS 30525-89-4 Information

Chemical Name | Paraformaldehyde |

Other Name | Paraformaldehyde solution; Paraformaldehyde sigma; Para formaldehyde; Paraformaldehyde PFA |

CAS | 30525-89-4 |

EINECS | 608-494-5 |

Type | Inorganic salts; Pharmaceutical, pesticide, dye intermediates |

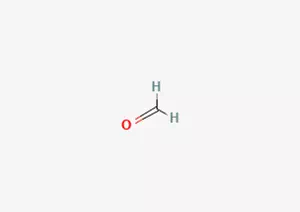

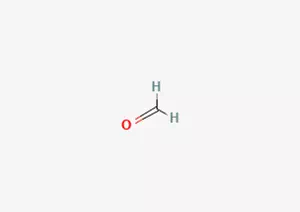

Molecular Formula | (CH2O)n |

Molecular Weight | 90.08 |

Paraformaldehyde CAS 30525-89-4 Properties

Melting point | 120-170 °C (lit.) |

Boiling point | 107.25°C (rough estimate) |

density | 0.88 g/mL at 25 °C (lit.) |

vapor density | 1.03 (vs air) |

vapor pressure | <1.45 mm Hg ( 25 °C) |

refractive index | 1.4540 (estimate) |

Fp | 158 °F |

storage temp. | 2-8°C |

solubility | chlorophenol above 70°C: soluble |

form | prilled |

color | White to off-white |

Odor | odor of formaldehyde |

PH | 5.5 (H2O, 20℃)(saturated solution) |

PH Range | 4 – 5.5 |

explosive limit | 7-73%(V) |

Water Solubility | sparingly soluble |

Stability: | Stable. Incompatible with strong acids, organic acids, strong oxidizing agents, oxides, alkalies, strong bases, amines. Combustible. Dust may form an explosive mixture with air. Liberates poisonous gases on combustion. |

What is Paraformaldehyde CAS 30525-89-4?

In the vast world of chemistry, Polyoxymethylene (named Polyoxymethylene by IUPAC according to the naming rules established by the International Union of Pure and Applied Chemistry, abbreviated as POM) plays a unique and significant role. Essentially, it is a polymer form of formaldehyde. However, the formaldehyde here is not the small-molecule formaldehyde in the ordinary sense, but polyoxymethylene with high molecular weight characteristics. From its structural perspective, it generally presents a specific aggregated state, with the structural length ranging from 8 to 100 units.

It is worth mentioning that long-chain polyoxymethylene has unique applications in the industrial field and is often used in the manufacturing of heat-resistant plastics. This heat-resistant plastic made from long-chain polyoxymethylene also has another well-known name - polyoxyethylene plastic (POE). For instance, the Delin product produced by DuPont is a typical representative of such materials.

Paraformaldehyde has a rather prominent characteristic, that is, its decomposition rate is extremely rapid. Once it undergoes a decomposition reaction, it will release formaldehyde gas with a slight odor. This characteristic makes it necessary to pay special attention to its decomposition situation and possible impact on the surrounding environment in many chemical reactions and practical applications.

The molecular formula of paroxymethylene is HO - (CH₂O)ₙ -h, where n represents the level of polymerization, and the value of n is defined as ranging from 8 to 100. Polyoxymethylene has a variety of alternative names, such as polyoxymethylene, polyacetal and solid formaldehyde, etc. These different names reflect its chemical composition or physical form characteristics from different perspectives.

In terms of appearance, polyoxymethylene presents as white granular or powder-like substances. When it is placed in a hot water environment, it can dissolve in it quickly. In cold water, it only dissolves slightly. In addition, it can also dissolve in dilute acids and water-soluble alkaline solutions. These solubility characteristics provide corresponding reference basis for its operation and handling in various chemical reactions and practical application scenarios.

However, it is necessary to pay high attention to the fact that the harm caused by polyoxymethylene to the human body is actually the same as that of formaldehyde. Not only that, as it takes on forms such as powder, there is an additional risk of dust. This means that corresponding protective measures need to be taken during contact, storage and transportation to prevent adverse effects on human health and the surrounding environment.

In terms of chemical properties, polyoxymethylene and formaldehyde share a great deal of similarity, and their performances in many chemical reactions are quite similar. For this reason, paraformaldehyde often exists in the commercial field as a special substitute for formaldehyde remedies, and in certain specific circumstances, it can play a similar role to formaldehyde, meeting the corresponding production or experimental requirements.

In addition, anhydrous formaldehyde has extremely wide applications in the field of organic synthesis. And polyoxymethylene, with its chemical properties similar to those of formaldehyde, often needs to use anhydrous formaldehyde as the basic raw material to participate in numerous complex synthetic reactions, contributing its own strength to the preparation of various chemical substances with specific functions.

Paraformaldehyde CAS 30525-89-4 Uses

Among the numerous applications in the field of chemistry, paraformaldehyde plays a unique and significant role. Among them, it is widely used in the cross-linking process of proteins and DNA, and this application is particularly prominent in the chip (chromatin immunoprecipitation) technology. Specifically, chromatin immunoprecipitation is a sophisticated strategy aimed at identifying the exact binding sites of certain healthy proteins to DNA, and paraformaldehyde plays a key role in this process.

Not only that, paraformaldehyde also has the ability to change the properties of water-based formaldehyde. Through a series of chemical reactions, it can generate resin-bonded materials. This characteristic makes paraformaldehyde have certain application value in the field of materials science as well.

However, it should be made clear that paraformaldehyde itself is not a fixative. In practical application scenarios, it needs to go through a depolymerization process and be transformed into formaldehyde in the solution before it can play its corresponding role. For instance, during the cell culture process, the conventional formaldehyde treatment procedures have strict operational norms. Among them, phosphate buffered saline (PBS) containing 4% formaldehyde is usually used and applied on ice for 10 minutes to ensure the effect and stability of cell treatment.

In the preparation of tissue and pathological specimens, there are also specific operation procedures. Under normal circumstances, a treatment process of at least 24 hours is carried out using 10% neutral buffered formalin (containing 4% formaldehyde) to ensure the quality of the specimens and the accuracy of subsequent analysis.

When paraformaldehyde undergoes depolymerization, the resulting formaldehyde has multiple uses. It can be used as a fumigant to fumigate objects or Spaces in a specific environment. It can also act as an antibacterial agent to inhibit the growth and reproduction of bacteria. As a bactericide, it effectively kills all kinds of harmful microorganisms. At the same time, it can also be used as a fixative to fix samples in relevant experiments and research for subsequent observation and analysis.

In terms of material manufacturing, polycarbonate made from long-chain (high-molecular-weight) polyoxymethylene is known as polyoxymethylene plastic (POM, Delrin). This material has had significant applications in the medical field. For instance, it was used in the renowned Sargenti root canal treatment.

In addition, paraformaldehyde also has important applications in agriculture and the chemical industry. It is mainly used in the production and application of herbicides. Through specific formulas and processes, it can produce highly efficient herbicide products, helping farmers effectively remove weeds in farmland and ensuring the growth of crops. Meanwhile, paraformaldehyde can also be used to prepare artificial resins, such as artificial corner products or artificial ivory, etc. During the preparation of these artificial materials, the characteristics of polyoxymethylene enable it to simulate certain properties of natural materials and meet different production requirements. Moreover, it can also be used to produce adhesives, providing reliable solutions for the bonding of various materials.

In the fields of medicine and health, paraformaldehyde also has extensive applications. In the pharmaceutical market, it is used as an energy component in contraceptive lotions, providing important raw material support for the research and development and production of contraceptive products. In the daily disinfection work of pharmacies, clothing and bedding, etc., paraformaldehyde can also play an important role, effectively killing bacteria and ensuring the hygiene and safety of related products. In addition, paraformaldehyde can also be used as a fumigant, disinfectant, fungicide and insecticide, etc. In different environments and scenarios, it contributes to ensuring public health and safety.

Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

*The packing also can be according the customers` requirment.

*Any inquiries will be replied within 24 hours.

*we provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.