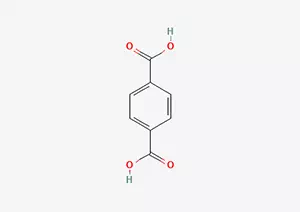

In the rich and colorful chemical world, terephthalic acid, as an organic substance with unique properties, plays an extremely important role. Its chemical formula is c6h4 (COOH) 2. This precise chemical formula is like its unique "ID card", clearly defining its molecular structure and composition.

Visually, terephthalic acid appears as a colorless solid. In the business field, it is a highly regarded chemical with extensive and significant application value. Among them, one of the most prominent uses is as a precursor for polyester pet dogs. In this specific application scenario, terephthalic acid plays an indispensable role, providing crucial raw material support for the production of polyester pet dogs.

Not only that, terephthalic acid also makes significant contributions in the manufacturing of clothing and plastic containers. In the field of clothing manufacturing, the polyester fibers it participates in constructing have excellent strength, wear resistance and comfort, making the clothes we wear daily more durable and beautiful. In the production of plastic containers, the presence of terephthalic acid helps enhance the toughness, transparency and chemical stability of the containers, ensuring that they can safely hold various items, especially food and beverages. Every year, millions of piles of terephthalic acid are produced worldwide. This huge output is sufficient to prove its important position in industrial production.

It is worth mentioning that terephthalic acid is one of the three isomers of phthalates. This special chemical structure endows it with unique physical and chemical properties, enabling it to exhibit various characteristics in different chemical reactions and application scenarios.

Terephthalic acid (PTA), as one of the important bulk organic raw materials, its influence has permeated all aspects of the national economy. In the field of chemical fibers, it is a key raw material for the production of various high-performance fibers. In the light industry, it provides a solid foundation for the manufacturing of various products. In the field of electronics, it also has its own place, assisting in the production and research and development of electronic devices. It can also play a certain role in the construction industry. It can be said that the application scope of PTA is extensive and diverse.

However, the application of PTA also shows a relatively concentrated characteristic. Globally, over 90% of PTA is used to produce polyethylene terephthalate (household PET). This extensive application ratio has formed a close connection between PTA and PET. In the production process of PET, the production of one ton of animal requires 0.85-0.86 tons of PTA and 0.33-0.34 tons of MEG (ethylene glycol). This precise proportioning relationship reflects the rigor and scientific nature of chemical reactions.

Polyester materials are further classified into multiple categories based on their distinct properties and applications, such as fiber sheets, polyester fiber sheets, container sheets, and film sheets. In the domestic market, the application distribution of PTA also has a clear division. Among them, approximately 75% of PTA is used for the production of polyester fibers. Polyester fiber, with its excellent properties such as high strength, good elasticity and durability, is widely used in the textile industry, providing people with comfortable, beautiful and durable clothing fabrics.

In addition, approximately 20% of PTA is used to produce bottle-grade polyester. This bottle-grade polyester is typically used for packaging many beverages, especially carbonated ones. It has the advantages of transparency, non-toxicity and corrosion resistance, which can effectively protect the quality and safety of beverages, and at the same time show the attractive color of beverages.

The remaining approximately 5% of PTA is used for the production of film-grade polyester. Film-grade polyester is mainly used in fields such as product packaging, films and tapes. It has excellent flexibility, barrier properties and sealing performance, and can provide reliable packaging protection for various products.

Looking back at the history of terephthalic acid, 1846 was a landmark year. At that time, the renowned French chemist Eminem Cayo (1805-1884), with his outstanding scientific research capabilities and unremitting spirit of exploration, successfully isolated terephthalic acid from turpentine for the first time. This great discovery laid the foundation for the subsequent research and application of terephthalic acid.

After World War II, terephthalic acid played a crucial role in industry. With the continuous advancement of science and technology, people have conducted in-depth research and exploration on the production process of terephthalic acid. Among them, the preparation of terephthalic acid by oxidizing para-xylene with dilute nitric acid is a common method. During this process, air oxidation of para-xylene will produce para-toluene, and para-toluene has the property of being able to resist further air oxidation.

Interestingly, p-tolueneformic acid can be converted into methyl p-tolueneformate (CH3C6H4CO2CH3), and this conversion process is like opening a new door, opening up a way for further oxidation to generate methyl terephthalate. And monomethyl terephthalate can be further esterified to form dimethyl terephthalate.

In 1955, during the development process in the field of chemistry, Mid Century Corporation and ICI Company made an innovation of great significance. They introduced the method of promoting the oxidation of p-toluene to terephthalic acid by bromide. This innovative measure has far-reaching implications. It makes it possible to directly convert para-xylene into terephthalic acid without separating intermediates, significantly enhancing production efficiency, reducing production costs, and bringing new opportunities and development space for the industrial production of terephthalic acid.