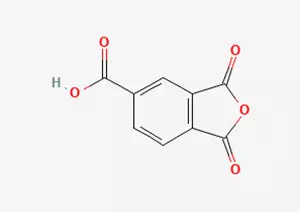

Among the numerous substances in the field of chemical engineering, there is an important compound, whose full name is triphenyltrianhydride, and it is often abbreviated as partial anhydride in the industry. In terms of its precise chemical name, it is called 1,2, 4-phenyltricarboxylic anhydride. For the convenience of expression and memory, the abbreviation TMA is usually used to refer to it.

In terms of appearance, some anhydrides present a relatively regular form, specifically manifested as white blocky or granular solids. Analyzed at the microscopic molecular level, its molecular formula is clearly C9H4O5. Through professional calculation methods, its relative molecular mass can be determined to be 192.12. In terms of physical properties, it has a specific melting point and boiling point. The melting point is 168℃. When the temperature reaches this value, it will change from a solid state to a liquid state. And its boiling point is 390℃, which means that at this temperature, it will change from liquid to gas.

In terms of solubility, some anhydrides exhibit rather complex properties. It is readily soluble in water, acetone, ethyl acetate, and solvents such as N and N-dimethylformamide. In these solvents, it can be dispersed relatively evenly to form a stable solution system. However, in solvents such as carbon tetrachloride, ether and toluene, it is only slightly soluble, that is to say, the amount dissolved in these solvents is relatively small, making it difficult to form high-concentration solutions.

A thorough exploration of its chemical properties reveals that due to the ingenious presence of bifunctive groups, namely carboxylic acid and anhydride groups, in the molecular structure of some anhydrides, this unique structure endows it with bifunctive chemical properties, enabling it to exhibit extremely high reactivity in chemical reactions. With this characteristic, it has extremely wide applications in the field of chemical production. It is like a universal "raw material cornerstone", which can be used to produce a series of highly valuable specialty chemicals and is an indispensable important chemical raw material in the modern new material research and development and production process.

In terms of the sources of chemical raw materials, pseudo-aromatic hydrocarbons (mainly composed of 1,2, 4-trimethylbenzene) in aromatic carbon nine fractions such as coal tar fractions, cracked gasoline and catalytic reforming gasoline can be converted into phenyltricarboxylic acids through a series of rigorous and scientific technological treatments, and then some anhydrides can be obtained. Specifically, the liquid-phase nitric acid oxidation method and the air oxidation method are adopted first. During this process, the action of cobalt or manganese catalysts is needed to facilitate the smooth progress of the reaction, thereby obtaining phenyltricarboxylic acid. Finally, through dehydration treatment, trimeric anhydride can be successfully produced.

And trimeric anhydride plays a crucial role in practical applications. It is mainly used for the production of plasticizers such as PVC resin plasticizers, which can endow PVC resin with better flexibility and processing performance. Polyimide resin coating endows it with excellent high-temperature resistance, corrosion resistance and other properties; Water-soluble alkyd resin has broadened the application scope and performance of alkyd resin. Epoxy resin curing agent, which helps to enhance the curing effect and related properties of epoxy resin; There are also low-voltage and pulse power supply container impregnating agents, films, water treatment agents, surfactants, etc. These applications cover multiple important fields such as chemical engineering and materials, and play a crucial role in promoting the development of related industries.