Dark green powder: It presents a rich and bright dark green color, with fine particles and a powder-like form. This powder has a unique color and texture. Under specific lighting conditions, it emits a steady and deep green luster.

Insoluble in water: When this powder is placed in water, it does not undergo any dissolution reaction with water and remains in its solid state, quietly settling at the bottom of water and forming a distinct stratification phenomenon with water. The two are immiscible and the boundary is clearly visible.

Good solubility in oily solvents: This powder demonstrates excellent solubility in various oily solvent environments. Whether it is common organic solvents such as toluene and xylene, or some specific oil-based solvents, it can be relatively easily dispersed and dissolved in them, forming a uniform and stable solution system, providing convenient conditions for subsequent applications.

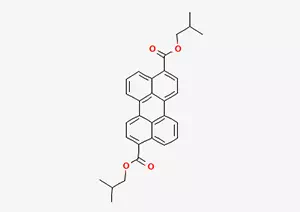

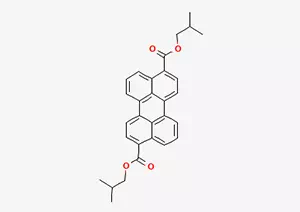

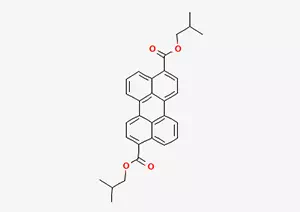

Solvent Green 5 is obtained by the reaction of 3, 9-perylene dicarboxylic acid and isobutanol in the presence of phosphorus trichloride and nitrobenzene as the solvent. In the specific chemical reaction process, all the required raw materials and solvents should be prepared first. 3, 9-perylene dicarboxylic acid and isobutanol were weighed and mixed in a certain proportion, and then the mixture was placed in a reaction system with nitrobenzene as the solvent. Meanwhile, phosphorus trichloride is added to this reaction system as a catalyst for the reaction or a key substance involved in the reaction. Under suitable reaction conditions such as temperature and pressure, a chemical reaction occurs between 3, 9-perylene dicarboxylic acid and isobutanol. After a series of complex chemical change processes, the product of solvent green 5 is finally generated.

Using 3, 9-perylene dicarboxylic acid and isobutanol as raw materials and nitrobenzene as the solvent, the two are condensed in the presence of phosphorus trichloride to obtain the product. Specifically, before the reaction starts, an appropriate amount of 3, 9-perylene dicarboxylic acid and isobutanol are precisely weighed and placed in a specific reaction vessel. Next, pour in nitrobenzene as the solvent to ensure that the raw materials can be fully dissolved and mixed in it. Subsequently, phosphorus trichloride is slowly added to initiate the reaction. During the reaction process, the molecules of 3, 9-perylene dicarboxylic acid and isobutanol gradually approach each other and undergo condensation reactions under the action of phosphorus trichloride. Through the breaking and recombination of chemical bonds between molecules, new chemical structures are formed, and eventually the products we need are obtained.

After post-treatment steps such as solvent recovery and finished product drying: Once the reaction is completed, a series of post-treatment operations need to be carried out on the reaction system next. The first step is solvent recovery. Through specific separation techniques, the solvent nitrobenzene used in the reaction process is separated from the reaction mixture and recovered. This step not only enables the recycling of solvents and reduces production costs, but also meets environmental protection requirements. After the solvent recovery is completed, the remaining products are dried. Adopt appropriate drying methods and equipment to remove residual moisture and other volatile impurities in the product, ensuring its purity and quality.

The product contains a small amount of 3,10 isomers: In the final obtained product, in addition to the main components, there are also a small amount of 3,10 isomers. The existence of this isomer is due to the fact that during the chemical reaction process, the conformation and arrangement of molecules have a certain degree of randomness, resulting in some molecules forming 3,10 isomer structures that are similar in structure to but slightly different from the target product. Although its content is relatively small, to a certain extent, it will also affect some properties and application performance of the product.